In the quest for more efficient and cost-effective heating, ventilation, and air conditioning (HVAC) systems, perforated metal has emerged as a game-changing solution. This innovative material is revolutionizing the way we approach airflow management, leading to significant improvements in energy efficiency and overall system performance.

The Science Behind Perforated Metal in HVAC

Perforated metal sheets are engineered with precision-cut holes that allow for controlled air passage. This unique design offers several advantages:

1. Optimized Airflow: The arrangement and size of perforations can be customized to direct and regulate air movement.

2. Noise Reduction: Perforated metal can help dampen sound, creating quieter HVAC operations.

3. Structural Integrity: Despite the holes, perforated metal maintains strength and durability.

4. Aesthetics: It provides a sleek, modern look that can enhance the visual appeal of HVAC components.

Key Applications in HVAC Systems

Air Diffusers and Grilles

Perforated metal diffusers distribute air evenly across spaces, eliminating hot or cold spots and improving overall comfort.

Filtration Systems

When used in air filters, perforated metal supports filter media while allowing for efficient airflow, balancing filtration efficiency with energy consumption.

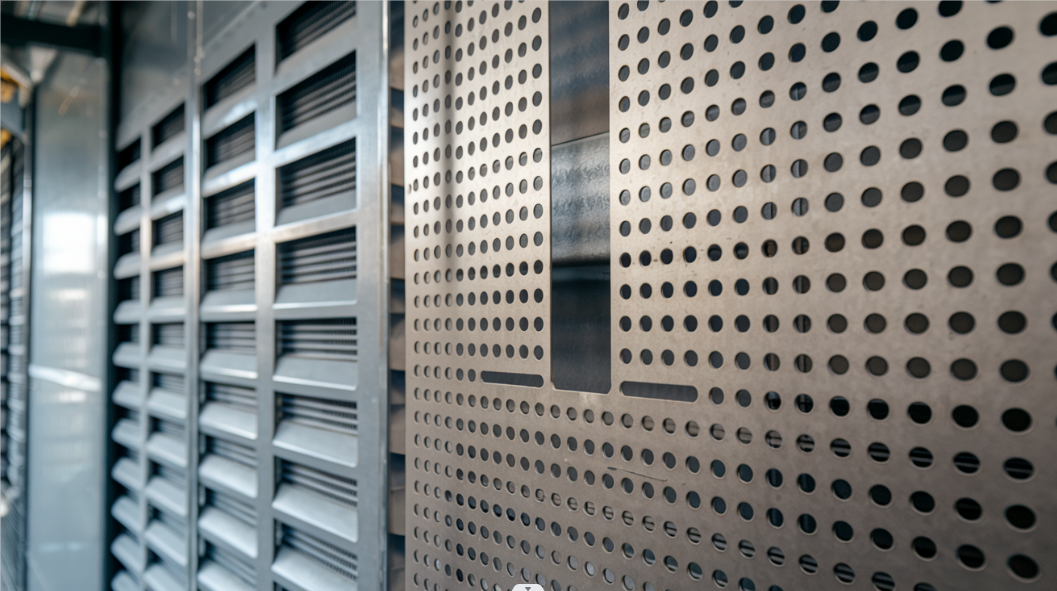

Equipment Enclosures

HVAC units housed in perforated metal enclosures benefit from improved ventilation, preventing overheating and extending equipment lifespan.

Case Studies: Perforated Metal in Action

Commercial Office Building

A 20-story office building in Chicago replaced traditional vents with perforated metal diffusers, resulting in a 12% reduction in energy costs and improved tenant satisfaction due to more consistent temperatures.

Industrial Manufacturing Facility

An automotive parts manufacturer integrated perforated metal into their paint booth ventilation system, achieving a 25% increase in airflow efficiency and reducing energy consumption by 18%.

Selecting the Right Perforated Metal Solution

When considering perforated metal for HVAC applications, key factors include:

l Hole size and pattern

l Open area percentage

l Material thickness and type (e.g., aluminum, stainless steel)

l Finish and coating options

Consulting with HVAC engineers and perforated metal specialists can help determine the optimal configuration for your specific needs.

The Future of HVAC: Energy Efficiency and Sustainability

As building codes become more stringent and energy costs continue to rise, the role of perforated metal in HVAC systems is set to grow. Its ability to enhance airflow while reducing energy consumption aligns perfectly with the industry’s push towards more sustainable and efficient solutions.

Conclusion

Perforated metal is more than just a material – it’s a key component in the evolution of HVAC technology. By improving airflow, reducing energy consumption, and offering versatile design options, it’s helping create more comfortable, efficient, and sustainable indoor environments.

Post time: Sep-27-2024