The application of metal corrugated packing mesh in distillation towers is mainly reflected in improving distillation efficiency and performance. The following is a detailed explanation of its application:

Performance improvements:

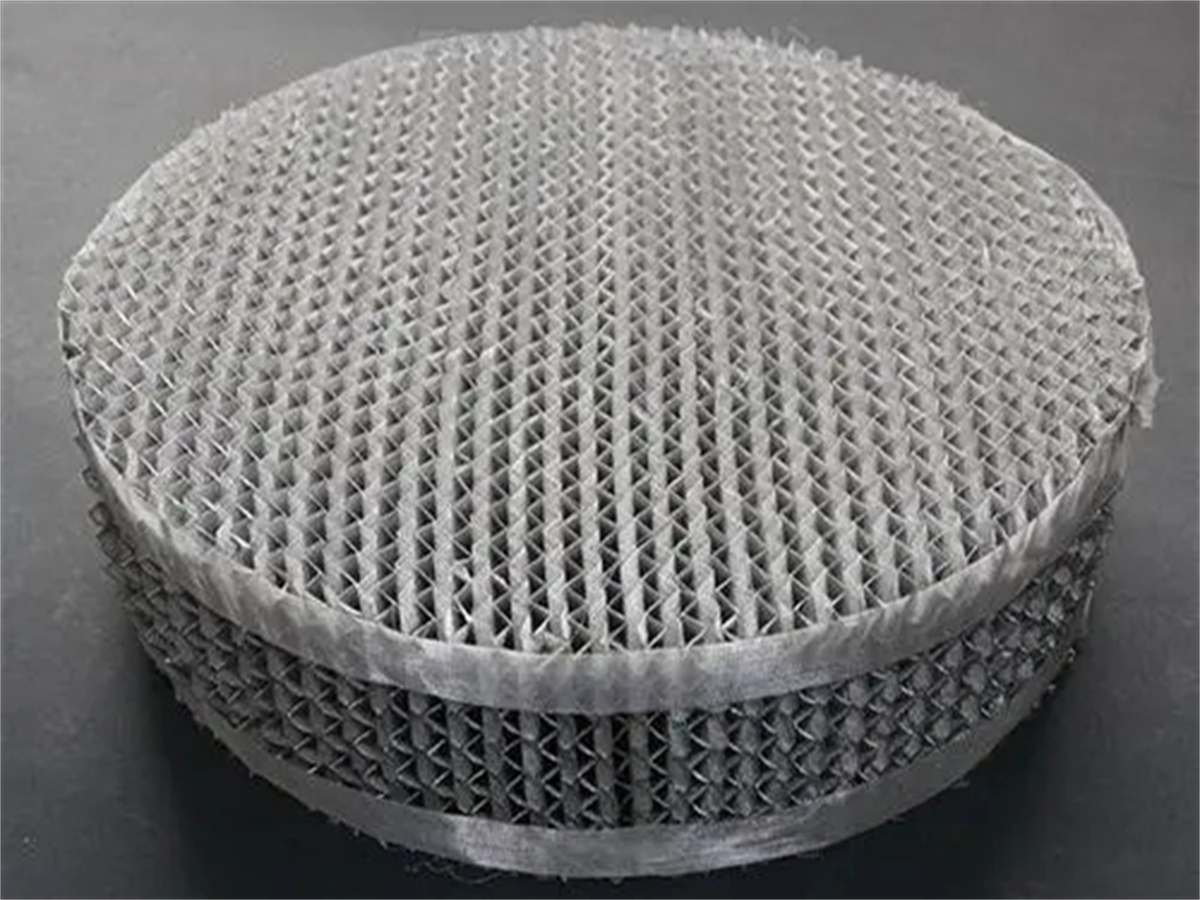

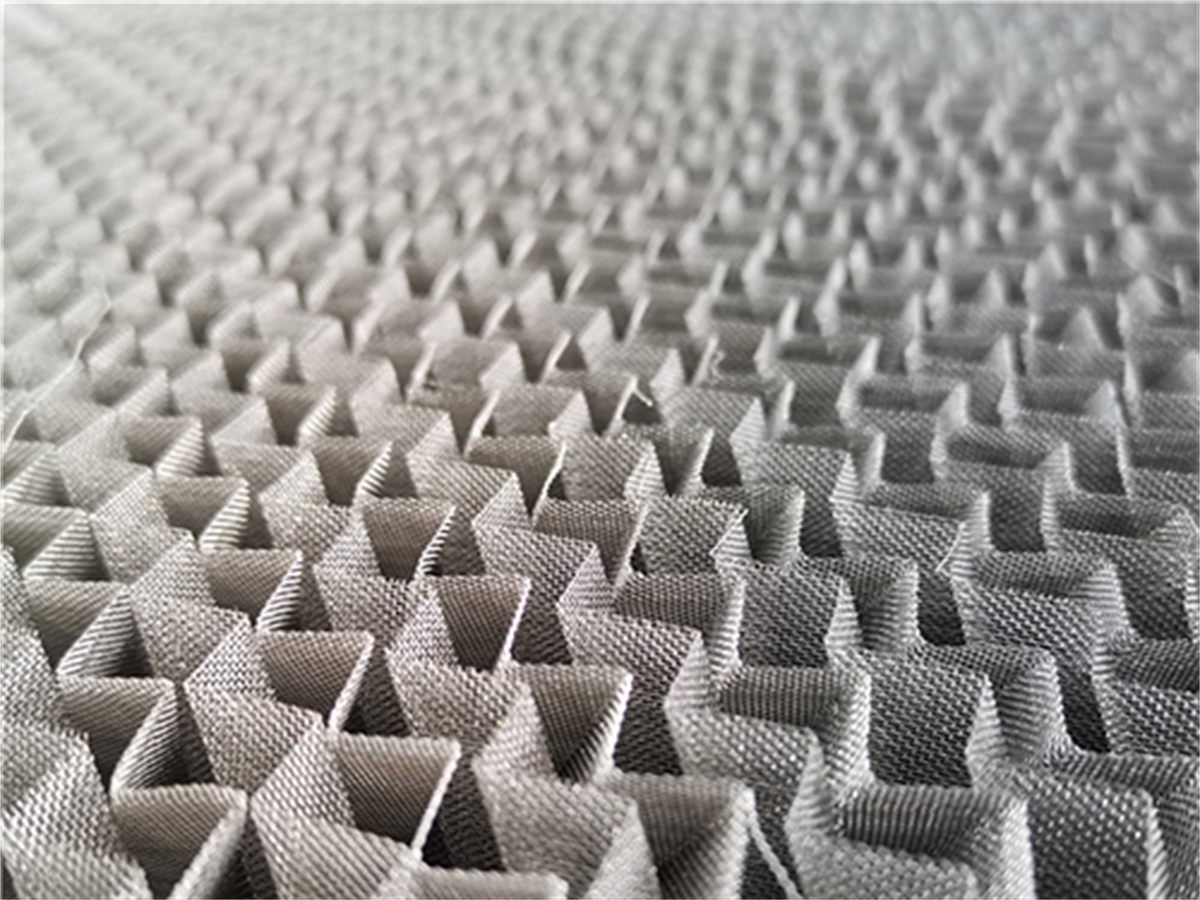

1.Distillation efficiency: Metal corrugated packing mesh, especially stainless steel wire mesh corrugated packing, can significantly improve distillation efficiency. There are small holes on the corrugated plate, which help to strengthen the uniform distribution of liquid and the renewal of liquid film, reduce dead corners in the packing, thereby improving separation efficiency.

2.Energy saving and consumption reduction: By optimizing the distillation process, the metal corrugated packing mesh can save a large amount of steam and reduce energy consumption. For example, after applying stainless steel wire mesh packing to the pre-distillation tower, all indicators exceeded the original design indicator requirements, while the tower load was increased, meeting the requirements for device expansion.

Types and selections:

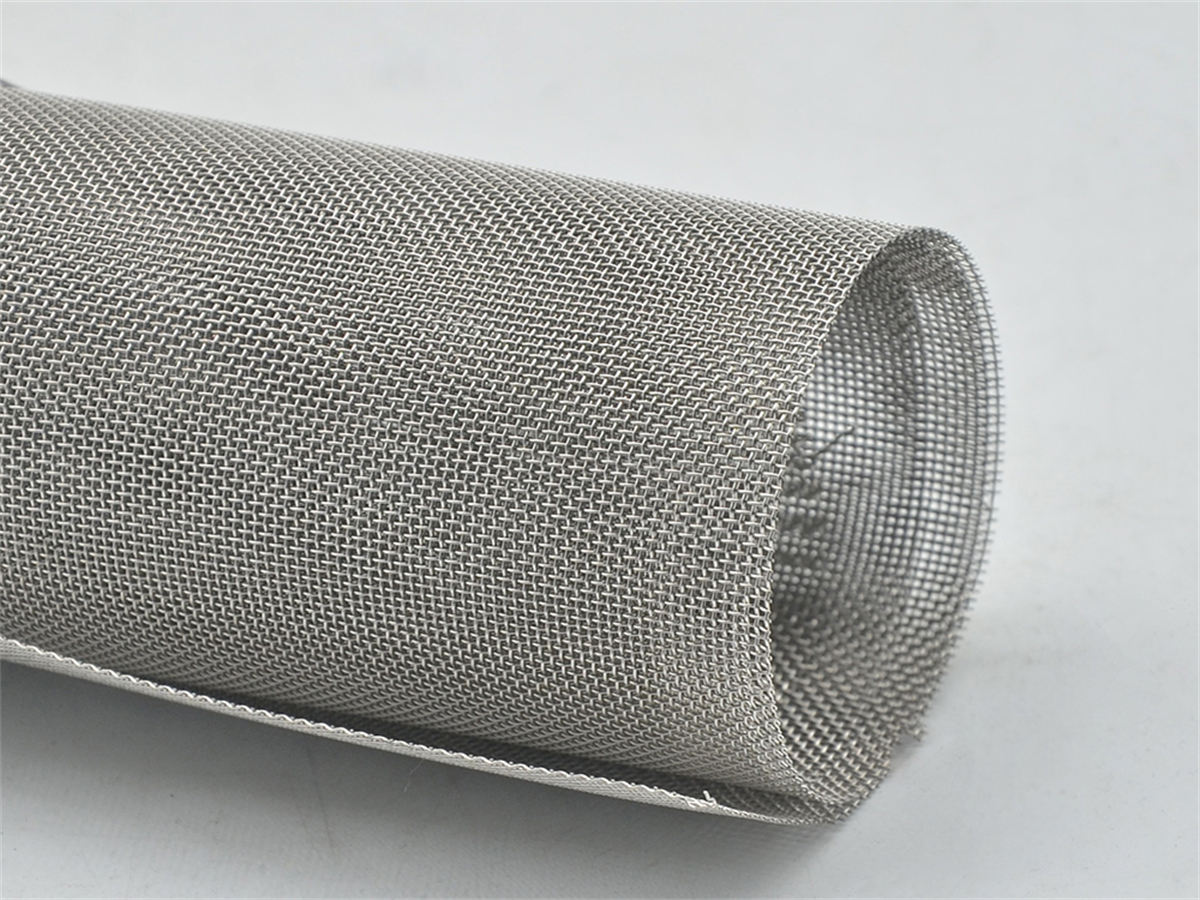

1.Filling type: Metal corrugated filling mesh can be divided into two categories: metal wire mesh and plastic wire mesh according to the material. In distillation columns, stainless steel corrugated structured packing and stainless steel wire mesh packing are common choices. Among them, BX500 wire mesh corrugated packing and CY700 structured packing are two common types.

2.Selection basis: The specific packing used can be determined according to the actual working conditions and the size of the distillation tower. For fine, large-scale, high-vacuum distillation equipment, metal corrugated packing mesh can meet its requirements, providing favorable conditions for the distillation of difficult-to-separate substances, heat-sensitive substances and high-purity products.

Post time: Jun-27-2024