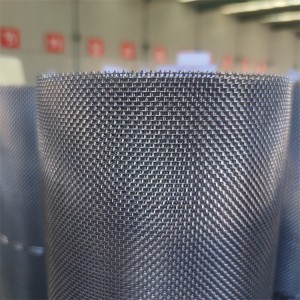

50 mesh Stainless Steel Mold Mesh

Stainless steel mold mesh is a critical component in the production of disposable tableware made from pulp mold. The mesh is used in the molding process to shape and form the pulp into the desired tableware items. Here’s a detailed look at the role and importance of stainless steel mold mesh in this context:

Role of Stainless Steel Mold Mesh

Filtration: The mesh acts as a filter, allowing water to drain away from the pulp while retaining the fibers. This helps in forming a solid and well-defined shape for the tableware.

Support and Structure: The mesh provides structural support to the pulp during the molding process, ensuring that the final product has the desired shape and strength.

Uniformity: The mesh ensures that the pulp is evenly distributed across the mold, leading to uniform thickness and consistency in the final product.

Durability: Stainless steel is chosen for its durability and resistance to corrosion, which is essential for maintaining the quality and longevity of the molds.

Characteristics of Stainless Steel Mold Mesh

Material: Made from high-quality stainless steel, which is resistant to rust, corrosion, and wear. This ensures a long lifespan and consistent performance.

Mesh Size: The size of the mesh openings can vary depending on the specific requirements of the tableware being produced. Finer meshes are used for more detailed and delicate items, while coarser meshes are suitable for larger, sturdier products.

Strength: Stainless steel mesh is strong enough to withstand the high pressures and temperatures used in the molding process.

Cleanability: Stainless steel is easy to clean and maintain, which is important for ensuring hygiene and preventing contamination in the production process.

Applications in Pulp Mold Tableware Production

Plates and Bowls: The mesh is used to form the basic shape of plates and bowls, ensuring they have smooth surfaces and consistent thickness.

Cups and Trays: For more complex shapes like cups and trays, the mesh helps in maintaining the structural integrity during the molding and drying processes.

Custom Designs: Stainless steel mesh can be customized to create intricate designs and patterns on the tableware, adding aesthetic value to the final products.

Packaging plastic mold dedicated network

Pulp molding factory

405060 mesh

Annealing Net

50 mesh plastic mesh

Pulp molded mesh

Filter screen for casting film machine

Egg tray plastic mesh

Meal box mold net

Forming mold

Transfer mold

Cold pressing mold

Heat setting mold

Network model

Pulp shoe support mold net

Egg tray equipment mold network