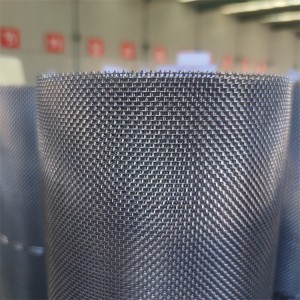

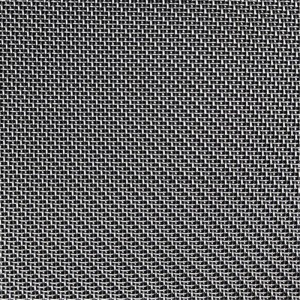

200/300/400mesh Lithium iron phosphate production screen

Lithium iron phosphate filter screen plays a crucial role in the new energy industry, mainly used for filtering and screening lithium iron phosphate materials.

1、 Material and Characteristics

Material: Lithium iron phosphate filter screens are usually made of stainless steel, such as 304 stainless steel or 316 stainless steel, which have excellent corrosion resistance and wear resistance, and can adapt to various harsh working environments.

characteristic:

The high precision of the sieve ensures that the filtered lithium iron phosphate material meets the particle size requirements.

The structure is sturdy, not easily deformed, and can withstand high working pressure.

Easy to clean and maintain, reducing production costs.

2、 Number of Contents and Selection

Mesh size: The mesh size of lithium iron phosphate filter screen is usually selected according to actual needs. Common mesh sizes include 25 mesh, 100 mesh, 200 mesh, 300 mesh, 400 mesh, etc. The higher the mesh size, the smaller the aperture of the sieve, and the finer the filtered material.

Suggestion for selection:

Select the appropriate mesh size based on the particle size requirements of lithium iron phosphate material.

Considering the characteristics of the working environment and materials, choose a mesh material with better corrosion resistance and wear resistance.

3、 Maintenance and upkeep

In order to ensure the long-term stable operation and extend the service life of lithium iron phosphate filter screens, regular maintenance and upkeep are required. Specific measures include:

Regular cleaning: Regularly clean impurities and dirt on the sieve to maintain its cleanliness and smoothness.

Inspection and replacement: Regularly check the wear of the screen mesh, and replace it promptly if there is severe wear or damage.

Storage and Preservation: When not in use, the sieve should be stored in a dry, ventilated, and non corrosive gas environment to prevent moisture, rust, or damage to the sieve.

Lithium iron phosphate filter screen has broad application prospects and market demand in the new energy industry. Choosing the appropriate mesh material, mesh size, and specifications is crucial for ensuring product quality and production costs. At the same time, regular maintenance and upkeep are also key to ensuring the long-term stable operation and extending the service life of the screen mesh.