Imeshi yesikrini sezimayini

Isikrini semayini siyisici sesakhiwo semeshi yensimbi esisetshenziselwa ukuhlola nokuhlunga. Isetshenziswa kabanzi ezimbonini zezimayini, zamalahle, ze-petroleum nakwezinye izimboni. Okulandelayo yisingeniso esivela ezintweni ezibonakalayo, isakhiwo, ukusebenza, ukusetshenziswa nokugcinwa:

1. Ukuhlukaniswa kwezinto ezibonakalayo

Izinto zensimbi

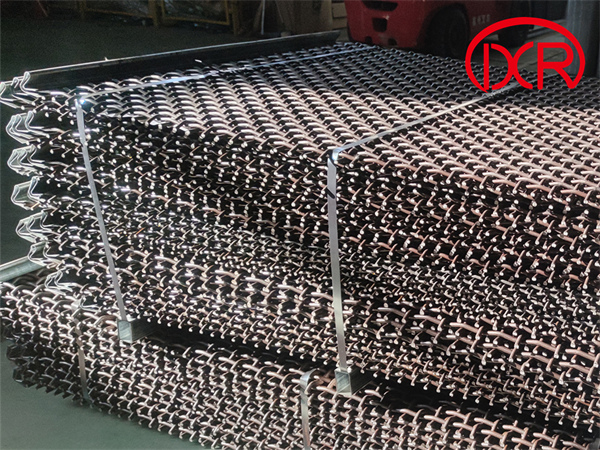

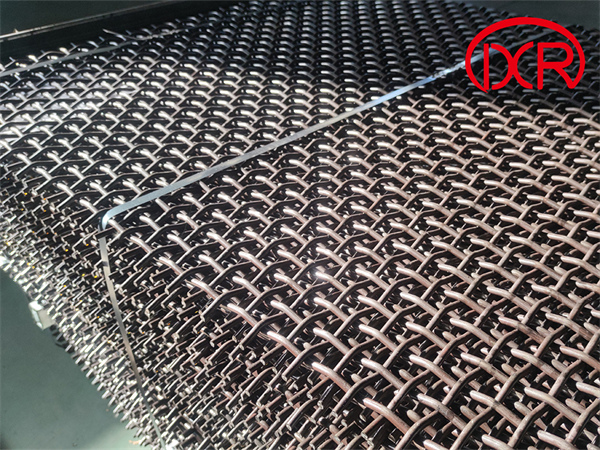

Isikrini sensimbi ye-manganese ephezulu: Silukwe ngocingo lwensimbi ye-manganese enobubanzi bocingo obungu-1.6mm~12mm. Amaphoyinti okugqagqana e-warp ne-weft awagqamanga, indawo yesikrini isicaba, amandla ayafana, futhi inopulasitiki obuhle nokuqina. Uma ingaphansi komthelela oqinile nokungqubuzana, indawo engaphezulu iba lukhuni ngenxa yokuguqulwa kwepulasitiki, futhi inani lokuqina lingakhushulwa libe ngaphezu kwe-HRC60. Inokumelana nokugqoka okuphezulu, futhi ipulasitiki yangaphakathi nokuqina kusephezulu. Impilo yesevisi ingafinyelela izikhathi ezi-4~8 kunezikrini ezijwayelekile. Isetshenziswa kakhulu ezimbonini ezinkulu zezimayini.

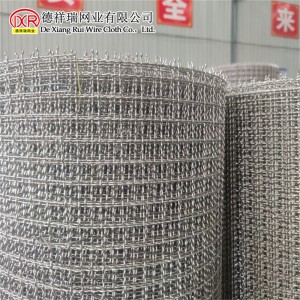

Isikrini sensimbi engagqwali: Izinto eziyinhloko zingama-201, 302, 304, 304L, 316, njll., zine-asidi enhle, i-alkali nokugqwala ukumelana, amandla aphezulu, amandla aqinile aqinile, ukuqina nokumelana nokugqoka, okuhlala isikhathi eside, ukumelana nokushisa okuphezulu kwe-oxidation (304 isikrini sensimbi engagqwali okuzisholo ukuthi izinga lokushisa lokumelana nokushisa lingafinyelela ku-830 ℃, insimbi engagqwali ukumelana ne-830 ℃ 1150 ℃), ukucubungula izinga lokushisa legumbi (ukucubungula ipulasitiki okulula, ukwenza ukusetshenziswa kwesikrini sensimbi engagqwali kuxutshwe), isiphetho esiphezulu (akukho ukwelashwa okungaphezulu okudingekayo, ukugcinwa kulula futhi kulula), njll., kuvame ukusetshenziselwa ukuhlola nokuhlunga ngaphansi kwezimo zemvelo ezine-asidi ne-alkali, kanye namanetha odaka embonini ye-petroleum, njengezikrini embonini ye-fiber yamakhemikhali, njll.

Isikrini esishiselwe: Sishiselwa ngezinto ezisetshenziswayo zokusetshenziswa zensimbi ephezulu ye-manganese, kusetshenziswa i-welding encane yamanje, engaqhubeki, noma ukupholisa ngenkathi sishiselwa ngamanzi, futhi izinduku zokushisela ziyizinduku zokushisela zensimbi ephakeme ye-manganese noma izinduku zokushisela zensimbi engenasici ye-austenitic.

Izinto ezingezona ezensimbi

Isikrini se-polyurethane: I-polyurethane ngokwayo ine-modulus enwebekayo ephezulu kakhulu, amandla aphezulu okumunca umthelela, ukumelana nokugqoka okuphezulu, namandla aphezulu okudonsa. Ngakho-ke, umthamo wayo wokuthwala uphakeme kakhulu, okungaphezu kwezikhathi ezingu-2.5 zamapuleti esikrini serabha. Impilo yayo yesevisi iphakeme ngokuphindwe izikhathi ezingu-8~10 kunaleyo yamapuleti esikrini sensimbi avamile, izikhathi ezi-3 kunezindawo zesikrini sensimbi engagqwali, kanye nezikhathi ezingu-3.9 kunerabha yemvelo. Yimpahla engaphezulu kwesikrini enokumelana kangcono nokugqokwa njengamanje. Impahla yayo yokukhiqiza ingeye-high molecular organic elastomer, enokumelana okuhle nokugqokwa, ukumelana nokuguquguquka, namandla amakhulu okuthwala. Ithole ukwelashwa okukhethekile ukuze kuqinisekiswe ukuthi ayisoze yaphela ngaphansi kwemithwalo eshintshanayo yesikhathi eside, futhi ifaneleka kakhulu ekuhlolweni kwezinto eziwashiwe.

2. Ifomu lesakhiwo

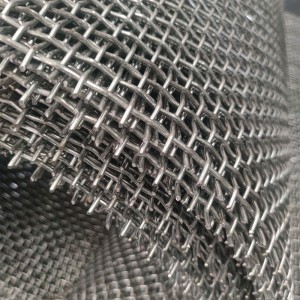

Imeshi elukiwe: elukwe ngocingo lwensimbi, enenani elikhulu lokuvula, elingafinyelela ku-75% wendawo yonke yesikrini, kodwa amandla aphansi, futhi ngokuvamile asetshenziselwa ukuhlola izinto zezinhlayiya ezinhle.

I-steel plate mesh: impilo yesevisi eqinile, ende, kodwa izinga lokuvula eliphansi uma kuqhathaniswa, elivame ukusetshenziselwa ukuhlola izinto ezinosayizi omaphakathi.

Isikrini sokubhoboza: Sebenzisa i-punch ukuze ukhiphe iphethini eqondiwe kupuleti okufanele licutshungulwe. Ngokuvamile yenziwe ngensimbi engagqwali, ipuleti le-aluminium, ipuleti lensimbi elishisayo nelibandayo, ipuleti lethusi, ifilimu yepuleti le-PVC nezinye izinto. Kunezinhlobo eziningi zemigodi, okuhlanganisa imigodi emide, imigodi eyisikwele, izimbobo eziyindilinga, izimbobo ezinezinhlangothi ezine, izimbobo zesikali sezinhlanzi, izimbobo ezeluliwe ezinomumo okhethekile, njll. Inezici zesisindo esilula, ezingasheleli, ukubukeka okuhle, ukusebenza kahle kokuhlunga, njll. Ivamise ukusetshenziswa emigomeni yokulawula umsindo endaweni kwezokuthutha nasezikhungweni zikamasipala, izikrini zokugaya, izikrini zezimayini, njll.

3. Izici zokusebenza

Izinga eliphezulu lokuhlola: Ingakwazi ukwehlukanisa ngokuphumelelayo izinto zobukhulu bezinhlayiyana ezihlukene futhi ithuthukise ukusebenza kahle kokuhlola.

Ingagugi futhi imelana nokugqwala: Ingakwazi ukuzivumelanisa nezimo zokuhlola eziyinkimbinkimbi, inciphise imvamisa yokushintshanisa, futhi yehlise izindleko zebhizinisi.

I-Anti-slip kanye ne-vibration-resistant: Ihlala izinzile phakathi nenqubo yokuhlola, inciphisa ukuvinjelwa kwezinto kanye nokulimala kwesikrini.

Ukunwebeka okuqinile nokuqina: Ine-elasticity ethile namandla okuguquka, futhi ingakwazi ukuzivumelanisa nezinsimbi ezinobukhulu obuhlukahlukene bezinhlayiyana kanye nokuma.

Akukho ukusondelana ndawonye: Isikrini sihlala siyisicaba ngesikhathi senqubo yokuhlola, futhi akukho senzakalo sokusondelana okwenzekayo, okuqinisekisa umphumela wokuhlola.

4. Inkambu yohlelo lokusebenza

Izikrini zezimayini zifanele izinhlobonhlobo zemishini yezimayini kanye nokugeleza kwenqubo, njengama-crusher, izigayo, ama-concentrator, njll., ezingafinyelela ukuhlolwa kwe-ore, ukugredwa nokukhethwa.

5. Isondlo

Ukuhlolwa okuvamile kwesikrini: Kuyadingeka ukuhlola njalo ukuthi indawo yaso yonakele noma ikhubazekile, bese ubuyisela isikrini esilimele ngesikhathi.

Ukuhlanza isikrini: Isikrini esidlidlizayo sizokhipha uthuli oluningi ngesikhathi sokusebenza, futhi isikrini sidinga ukuhlanzwa njalo ukuze sigcinwe sihlanzekile futhi sigweme ukuvala izimbobo zesikrini.

Thuthukisa umthamo wokuphambukisa: Uma isikrini esimaphakathi sigqokwa kakhulu, amandla okuphambukisa angathuthukiswa noma iphakathi lesikrini linganyuselwa ku-arc ephezulu.