i-red copper wire mesh

I-red copper wire mesh iwumsebenzi we-mesh olukwe ngocingo lwethusi oluhlanzeke kakhulu (okuqukethwe kwethusi okumsulwa kuvamise ukuba ≥99.95%). Ine-conductivity kagesi enhle kakhulu, i-thermal conductivity, ukumelana nokugqwala kanye nokusebenza kokuvikela i-electromagnetic, futhi isetshenziswa kakhulu kwezobuchwepheshe, ezokuxhumana, ezempi, ucwaningo lwesayensi nakweminye imikhakha.

1. Izici zezinto ezibonakalayo

Izinto zethusi ezihlanzekile kakhulu

Ingxenye eyinhloko ye-copper wire mesh iyithusi (Cu), evame ukuqukatha inani elincane lezinye izakhi (ezifana ne-aluminium, i-manganese, njll.), enobumsulwa obungaphezu kuka-99.95%, okuqinisekisa ukuzinza kwezinto ezindaweni ezihlukahlukene.

Excellent conductivity kagesi kanye ezishisayo

I-Copper ine-conductivity ephezulu kagesi kanye ne-thermal futhi ifanele izinhlelo zokusebenza ezidinga ukuqhutshwa kahle kukagesi, njengokuxhuma, ukubeka phansi kanye nokuchithwa kokushisa kwemishini kagesi.

Ukumelana nokugqwala okuhle

I-Copper inokumelana okuhle nokugqwala ezindaweni eziningi futhi ifanele ukuhlobisa kwangaphakathi nangaphandle, ukubaza nezinye izinhlelo zokusebenza.

Okungewona uzibuthe

I-Copper wire mesh ayiwona uzibuthe futhi ifanele izikhathi lapho ukuphazamiseka kazibuthe kumele kugwenywe.

Ipulasitiki ephezulu

I-Copper kulula ukucubungula ibe yizimo ezihlukahlukene, ezingahlangabezana nezidingo zemiklamo eyinkimbinkimbi futhi ivame ukusetshenziswa ekukhiqizeni imisebenzi yobuciko kanye nemihlobiso.

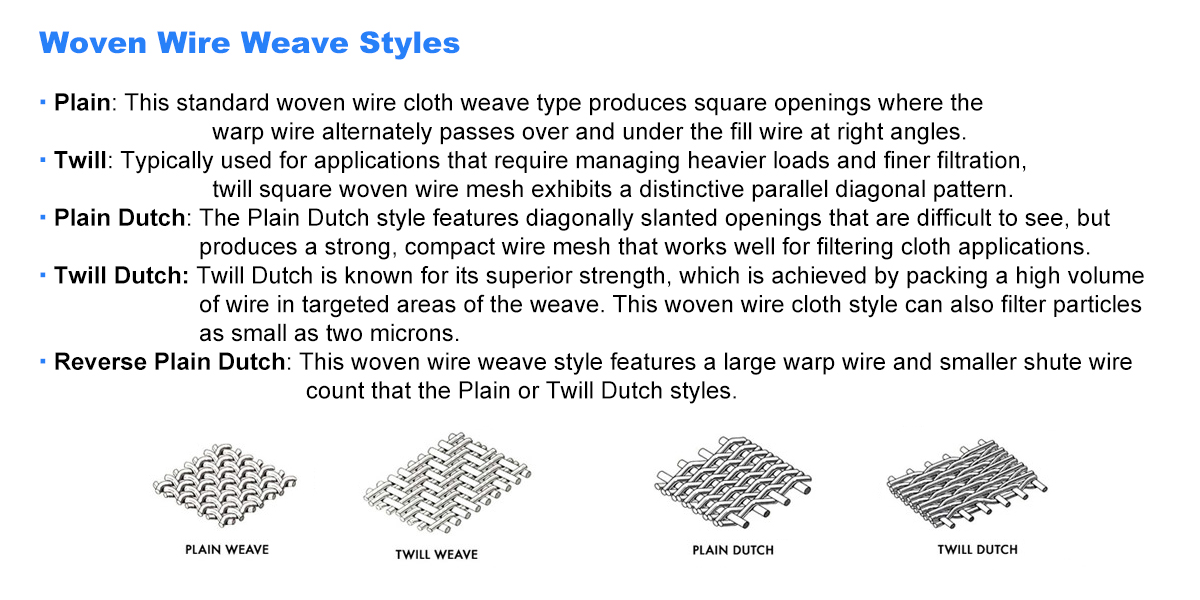

2. Inqubo yokweluka

I-copper wire mesh yenziwe ngezinqubo ezilandelayo:

I-Plain weave: Usayizi wemeshi usuka ku-2 kuye ku-200 meshes, futhi usayizi wemeshi umfaniswano, ofanele ukuhlungwa okujwayelekile nokuvikelwa.

I-Twill weave: Usayizi wemeshi uthambekele, ongahlunga izinhlayiya ezinhle, uthuli, njll., futhi ulungele izikhathi ezidinga ukuhlungwa okunembayo okuphezulu.

Imbobo enezimbobo: Imbobo eyenziwe ngokwezifiso yakhiwa inqubo yokugxiviza, enendawo encane yokuvula engama-microns angu-40, esetshenziselwa kakhulu ukuchithwa kokushisa kwe-VC nokuvikela i-electromagnetic.

I-Rhombus stretched mesh: Ibanga lokuvula lingu-0.07 mm ukuya ku-2 mm, elilungele ukwakha isivikelo nokuvikela igagasi logesi.

3. Imininingwane

Ububanzi bentambo: 0.03 mm kuya ku-3 mm, ongenziwa ngokwezifiso ngokuya ngezidingo.

Usayizi wemeshi: 1 kuya ku-400 meshes, ukuphakama kosayizi we-mesh, kuncane indawo yokuvula.

Usayizi wemeshi: 0.038 mm ukuya ku-4 mm, ohlangabezana nezidingo ezihlukile zokunemba kokuhlunga.

Ububanzi: Ububanzi obujwayelekile buyimitha elingu-1, futhi ububanzi obukhulu bungafinyelela kumamitha angu-1.8, obungenziwa ngokwezifiso.

Ubude: Kungenziwa ngezifiso ukusuka kumamitha angama-30 kuye kwangamamitha ayi-100.

Ubukhulu: 0.06 mm ukuya ku-1 mm.

IV. Izinkambu zohlelo lokusebenza

Imishini kagesi

Isetshenziselwa ukuvikela ukuphazamiseka kwe-electromagnetic ngaphakathi kwemishini kagesi futhi ivimbele imisebe ye-electromagnetic ukuthi ithinte umzimba womuntu nezinye izinto zokusebenza. Isibonelo, i-copper mesh ivame ukusetshenziselwa ukuvikela imisebe ye-electromagnetic emishinini kagesi njengamakesi ekhompyutha, iziqapha, nomakhalekhukhwini.

Inkambu yokuxhumana

Eziteshini eziyisisekelo zokuxhumana, ezokuxhumana ngesathelayithi nezinye izinto zokusebenza, i-copper mesh ingasetshenziswa ukuvikela ukuphazamiseka kwamagnetic kwangaphandle nokuqinisekisa ikhwalithi yezimpawu zokuxhumana.

Inkambu yezempi

Isetshenziselwa ukuvikela i-electromagnetic yemishini yezempi ukuvikela amathuluzi ezempi ekuphazamisekeni nasekuhlaselweni yizitha zikagesi.

Inkambu yocwaningo lwesayensi

Kulabhorethri, i-copper mesh ingasetshenziswa ukuvikela ukuphazamiseka kwamagnetic kwangaphandle nokuqinisekisa ukunemba kwemiphumela yokuhlola.

Umhlobiso wezakhiwo

Njengendwangu yokuvikela udonga lwamakhethini, ihlanganisa ukusebenza kanye nobuhle futhi ifanele amakamelo eseva yekhompiyutha ephezulu noma izikhungo zedatha.

Ukuhlolwa kwezimboni

Isetshenziselwa ukuhlunga imishayo ye-electron futhi ihlukanise izixazululo ezixubile, ezinosayizi wemeshi ukusuka ku-1 mesh kuya ku-300 mesh.

Isici sokukhipha ukushisa

I-200 mesh plain mesh isetshenziswe kumarediyetha wethebhulethi ukusiza okokusebenza kwe-elekthronikhi ukuqeda ukushisa futhi kuthuthukise ukuzinza nempilo yesevisi yezisetshenziswa.

5. Izinzuzo

Impilo ende: ukumelana nokugqwala, ukumelana nezinga lokushisa eliphezulu, ukuncishiswa kwemvamisa yokushintsha, kanye nezindleko zokulungisa ezincishisiwe.

Ukunemba okuphezulu: Imeshi enembobo ingafinyelela usayizi wembotshana weleveli encane ukuze ihlangabezane nezidingo zokuhlunga okunembayo.

Ukwenza ngokwezifiso: Ububanzi bocingo, inombolo yemeshi, usayizi kanye nokwakheka kungenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende.

Ukuvikelwa kwemvelo: Impahla yethusi ingagaywa kabusha futhi ihlangabezane nezidingo zentuthuko esimeme.

| I-Mesh | I-Wire Dia (amayintshi) | I-Wire Dia (mm) | Ukuvula (amayintshi) |

| 2 | 0.063 | 1.6 | 0.437 |

| 2 | 0.08 | 2.03 | 0.42 |

| 4 | 0.047 | 1.19 | 0.203 |

| 6 | 0.035 | 0.89 | 0.131 |

| 8 | 0.028 | 0.71 | 0.097 |

| 10 | 0.025 | 0.64 | 0.075 |

| 12 | 0.023 | 0.584 | 0.06 |

| 14 | 0.02 | 0.508 | 0.051 |

| 16 | 0.018 | 0.457 | 0.0445 |

| 18 | 0.017 | 0.432 | 0.0386 |

| 20 | 0.016 | 0.406 | 0.034 |

| 24 | 0.014 | 0.356 | 0.0277 |

| 30 | 0.013 | 0.33 | 0.0203 |

| 40 | 0.01 | 0.254 | 0.015 |

| 50 | 0.009 | 0.229 | 0.011 |

| 60 | 0.0075 | 0.191 | 0.0092 |

| 80 | 0.0055 | 0.14 | 0.007 |

| 100 | 0.0045 | 0.114 | 0.0055 |

| 120 | 0.0036 | 0.091 | 0.0047 |

| 140 | 0.0027 | 0.068 | 0.0044 |

| 150 | 0.0024 | 0.061 | 0.0042 |

| 160 | 0.0024 | 0.061 | 0.0038 |

| 180 | 0.0023 | 0.058 | 0.0032 |

| 200 | 0.0021 | 0.053 | 0.0029 |

| 250 | 0.0019 | 0.04 | 0.0026 |

| 325 | 0.0014 | 0.035 | 0.0016 |