Imesh yesikrini semigodi

Isikrini semigodi sisixhobo sokwakheka kwemesh yentsimbi esetyenziselwa ukukhangela kunye nokucoca. Isetyenziswa kakhulu kwimigodi, amalahle, i-petroleum kunye namanye amashishini. Oku kulandelayo yintshayelelo evela kwimiba yemathiriyeli, ulwakhiwo, ukusebenza, ukusetyenziswa kunye nokugcinwa:

1. Ukuhlelwa kwezinto

Izinto zentsimbi

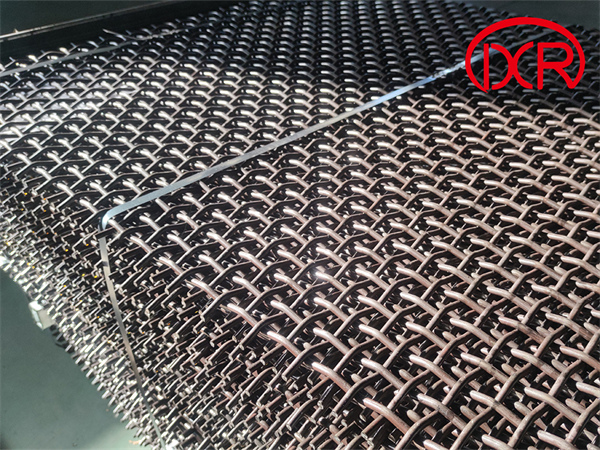

Isikrini sentsimbi yemanganese ephezulu: Silukwe ngocingo lwentsimbi yemanganese enobubanzi bocingo oluyi-1.6mm ~ 12mm. Amanqaku e-warp kunye ne-weft overlap ayibonakali, umphezulu wesikrini usicaba, amandla afanayo, kwaye aneplastiki elungileyo kunye nokuqina. Xa iphantsi kwempembelelo eyomeleleyo kunye nokukhuhlana, umphezulu wenziwe lukhuni ngenxa yokuguqulwa kweplastiki, kwaye ixabiso lobulukhuni linokonyuka ukuya ngaphezu kwe-HRC60. Inokumelana nokunxiba okuphezulu, kwaye iplastiki yangaphakathi kunye nokuqina kusephezulu. Ubomi benkonzo bunokufikelela kumaxesha angama-4 ~ 8 kwezikrini eziqhelekileyo. Isetyenziswa kakhulu kwimizi-mveliso yemigodi emikhulu.

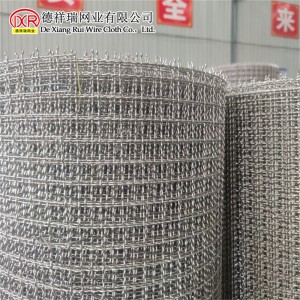

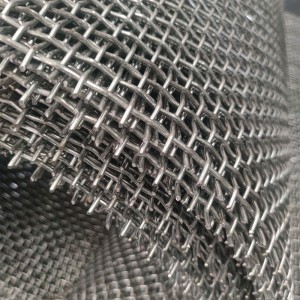

Stainless steel screen: Izinto eziphambili ziyi-201, 302, 304, 304L, 316, njl., kunye ne-asidi elungileyo, i-alkali kunye nokuxhathisa umhlwa, amandla aphezulu, amandla aqinile, ukuqina kunye nokumelana nokunxiba, ixesha elide, ukumelana nobushushu obuphezulu be-oxidation (i-304 yentsimbi ye-stainless screen ye-stainless steel nominal resistance yi-830 ℃, i-stainless steel resistance inokufikelela kwi-830 ℃ 1150 ℃), inkqubo yobushushu begumbi (ukusetyenzwa lula kweplastiki, ukwenza ukusetyenziswa kwesikrini sentsimbi exutywe ngentsimbi), ukugqiba okuphezulu (akukho nyango lomphezulu lufunekayo, ukugcinwa kulula kwaye kulula), njl.

Isikrini esidityanisiweyo: Sidityaniswe kwizinto eziluhlaza zentsimbi yemanganese, kusetyenziswa i-welding encinci yangoku, i-discontinuous welding, okanye ukupholisa ngelixa i-welding ngamanzi, kunye neentonga ze-welding ziphezulu zentsimbi ye-manganese ye-welding rods okanye i-austenitic stainless stainless welding rods.

Izinto ezingezizo ezentsimbi

Isikrini sePolyurethane: I-Polyurethane ngokwayo inemodyuli ephezulu kakhulu enwebekayo, amandla aphezulu okufunxa impembelelo, ukumelana nokunxiba okuphezulu, kunye namandla aphezulu okuqina. Ngoko ke, umthamo wayo wokuthwala uphezulu kakhulu, ongaphezu kwamaxesha angama-2.5 eepleyiti zesikrini serabha. Ubomi bayo benkonzo yi-8 ~ 10 ngamaxesha aphezulu kuneepleyiti zesikrini zetsimbi eziqhelekileyo, amaxesha ama-3 eendawo zesikrini zensimbi engenasici, kunye namaxesha angama-3.9 erabha yendalo. Yimathiriyeli yomphezulu wesikrini enokumelana ngcono nokunxiba okwangoku. Imveliso yayo yeye-molecular organic elastomer, enokumelana okugqwesileyo kokunxiba, ukumelana nokuguquguquka, kunye nomthamo omkhulu wokuthwala. Kuye kwenziwa unyango olukhethekileyo ukuze kuqinisekiswe ukuba akusayi kuze kuhlanjululwe phantsi kwemithwalo yexesha elide etshintshisayo, kwaye ifaneleke ngakumbi ukuhlolwa kwezinto ezihlanjiweyo.

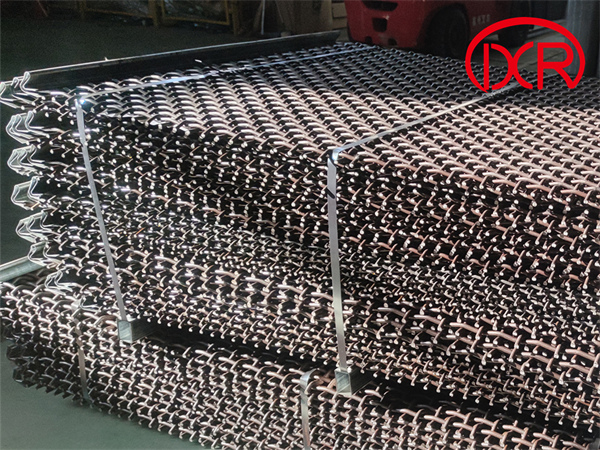

2. Ifom yesakhiwo

Umnatha olukiweyo: olulukiweyo olusuka kwintambo yentsimbi, enesantya esikhulu sokuvula, esinokufikelela kwi-75% yendawo yonke yesikrini, kodwa amandla aphantsi ngokwentelekiso, kwaye ahlala esetyenziselwa ukuvavanya imathiriyeli yamasuntswana amahle.

Umnatha wepleyiti yentsimbi: omelele, ubomi benkonzo ende, kodwa izinga lokuvula liphantsi, lisetyenziswa ngokubanzi ekuhlolweni kwemathiriyeli ephakathi.

Ukubhoboza isikrini: Sebenzisa i-punch ukukhupha ipateni ekujoliswe kuyo kwipleyiti ukuba iqhutywe. Ngokuqhelekileyo yenziwe ngensimbi engenasici, ipleyiti ye-aluminium, ipleyiti yentsimbi eshushu kunye nebandayo, ipleyiti yobhedu, ifilimu ye-PVC yepleyiti kunye nezinye izinto. Kukho iintlobo ezininzi zemingxuma, kubandakanywa imingxuma emide, imingxuma yesikwere, imingxuma ejikelezayo, imingxuma ene-hexagonal, imingxuma yesikali seentlanzi, imingxuma eyoluliweyo ekhethekileyo, njl.

3. Iimpawu zokusebenza

Izinga eliphezulu lokuhlola: Inokwahlula ngokufanelekileyo izixhobo zobukhulu bamasuntswana ahlukeneyo kunye nokuphucula ukusebenza kakuhle kovavanyo.

Ukunganxibi kunye nokungagugi: Iyakwazi ukuziqhelanisa nemeko yokuhlola entsonkothileyo, inciphise ukuphindaphindwa kokutshintshwa, kunye nokunciphisa iindleko zeshishini.

I-Anti-slip kunye ne-vibration-resistant: Ihlala izinzile ngexesha lenkqubo yokuhlola, ukunciphisa ukuvinjelwa kwezinto kunye nomonakalo wesikrini.

I-elasticity eyomeleleyo kunye nokuqina: Ine-elasticity ethile kunye ne-deformation umthamo, kwaye iyakwazi ukuziqhelanisa ne-ores yobukhulu bamasuntswana ahlukeneyo kunye neemilo.

Akukho kufutshane kunye: Isikrini sihlala sithe tyaba ngexesha lenkqubo yokuhlola, kwaye akukho nto isondeleleneyo eyenzekayo, iqinisekisa umphumo wokuhlola.

4. Indawo yosetyenziso

Izikrini zemigodi zifanelekile kwiindidi zezixhobo zemigodi kunye nokuhamba kwenkqubo, njengama-crusher, i-mills, i-concentrators, njl., Ezinokuthi zifezekise ukuhlolwa kwe-ore, ukuhlelwa kunye nokukhethwa.

5. Isondlo

Ukuhlolwa rhoqo kwesikrini: Kuyimfuneko ukujonga rhoqo ukuba umphezulu wayo wonakele okanye ukhubazekile, kwaye ubeke indawo yesikrini esonakalisiweyo ngexesha.

Ukucoca isikrini: Isikrini esingcangcazelayo siya kuvelisa uthuli oluninzi ngexesha lokusebenza, kwaye isikrini kufuneka sicocwe rhoqo ukusigcina sicocekile kwaye sinqande ukuvala imingxunya yesikrini.

Phucula umthamo wokuguqula: Ukuba umbindi wesikrini unxitywe kakhulu, umthamo wokuguqula unokuphuculwa okanye umbindi wesikrini unokunyuselwa kwi-arc ephezulu.