Wershada ODM Heerkulka Sare ee u adkaysta Mesh-xadhkaga birta ah

Waxaan awoodnaa inaan bixino alaab tayo sare leh, qiimo dagaal leh iyo kaalmada iibsadaha ugu weyn. Meeshayadu waa "Waxaad halkan ku timi si dhib leh waxaanan ku siinaynaa dhoola cadeyn si aad u qaadatid" Warshada ODM Tayada Sare ee Heerkulka Sare ee Xakamaynta Xargaha Xargaha, Waxaan kugu soo dhaweyneynaa inaad soo booqato warshadeena waxaanan rajeyneynaa inaad sameysid xiriir saaxiibtinimo oo ganacsi macaamiisha guriga iyo dibadda mustaqbalka dhow.

Waxaan awoodnaa inaan bixino alaab tayo sare leh, qiimo dagaal leh iyo kaalmada iibsadaha ugu weyn. Meeshayadu waa "Si dhib leh ayaad halkan ku timaaddaa, waxaanan ku siinaynaa dhoola-cadeyn aad ku qaadato"Metal China iyo Mesh silig, Waxaan diirada saareynaa bixinta adeega macaamiisheena oo ah cunsur muhiim ah oo lagu xoojinayo cilaaqaadka mudada dheer. Helitaankayada joogtada ah ee alaabooyinka heerkoodu sareeyo oo ay weheliso adeegeena iibka ka hor iyo iibka ka dib oo aad u wanaagsan waxa ay hubisaa tartan xoogan suuqa caalamiga ah ee sii kordhaya. Waxaan diyaar u nahay inaan iskaashi la samayno asxaabta ganacsiga ee gudaha iyo dibaddaba oo aan abuurno mustaqbal wanaagsan si wadajir ah.

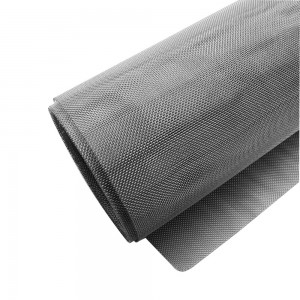

Mesh bir ah oo aan bir lahayn

Mesh birta aan la taaban karin waxaa loo qaybin karaa mesh silig bir ah oo aan bir lahayn, bir aan bir lahayn saddex mesh silig Heddie ah

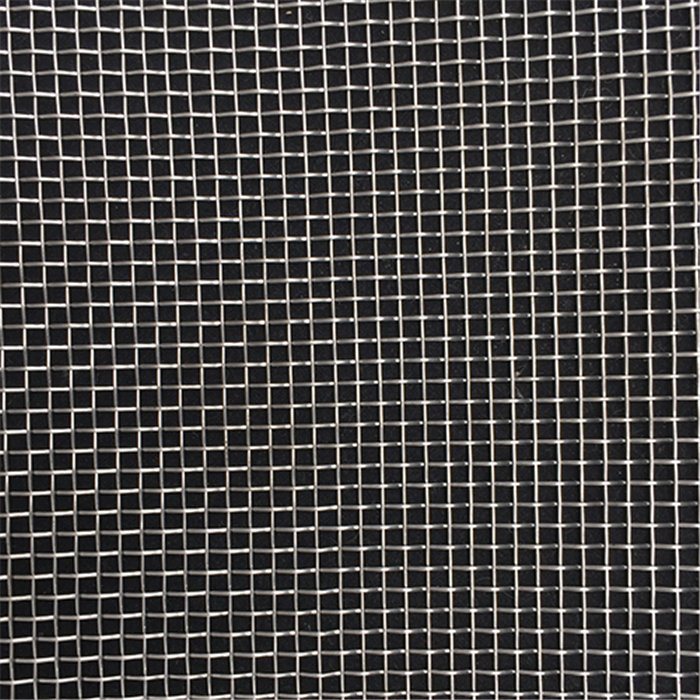

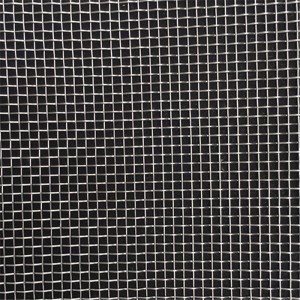

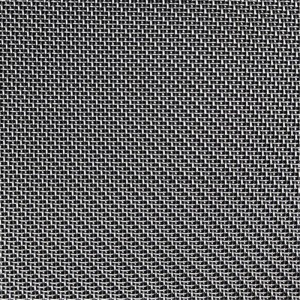

Alaabta siliga birta ah ee aan-dhalatada lahayn oogada saafiga ah:

nadiif ah, siman, magnet yar

Qalabka silig:

Birta Kaarboon: Low, Xiqh, Saliid Xanaaqa

Birta Aan Lahayn: Noocyada Magnetka Aan Ahayn 304,304L,309310,316,316L,317,321,330,347,2205,2207, Noocyada Magnetka 410,430 ect.

Qalabka gaarka ah: Copper, Brass, Bronze, Phosphor Bronze, copper, Aluminum, Nickel200, Nickel201, Nichrome, TA1/TA2, Titanium ect.

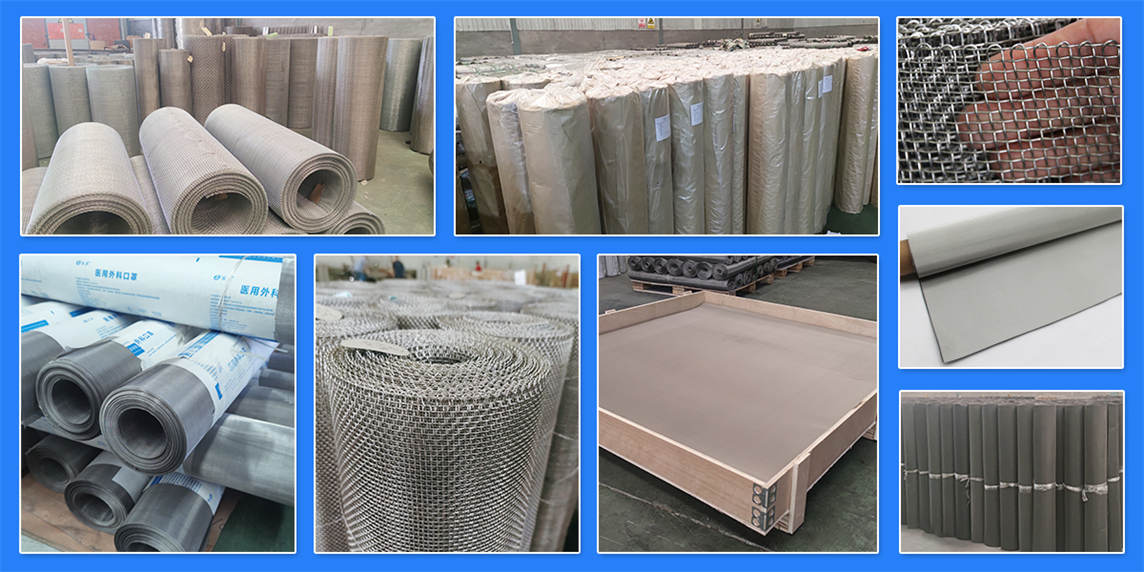

Baakad:

Biyo-Cadaynta , Warqad Caag ah, Kas alwaax ah, Baalley

Astaamaha Alaabta Mesh Wire-ka-Aan-la-aanta ah:

Kulaylka, aashitada, iska caabinta daxalka, xidhashada caabbinta. Dusha oo siman, nadiif ah, aan sun ahayn, caafimaad, ilaalinta deegaanka.

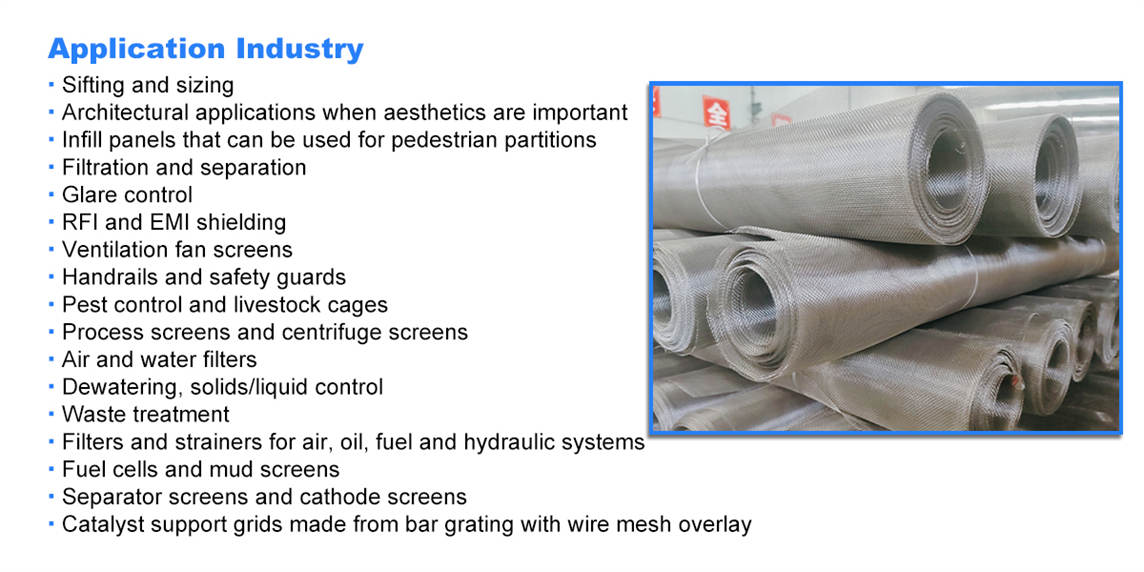

Alaabooyinka mesh birta ah ee birta ah ayaa isticmaala:

Kiimikooyinka: sifaynta xal aashitada, tijaabooyin kiimikaad, filter filter particulate kiimikaad, filter gaaska daxalka ah, sifaynta boodhka caustic

Saliid: saliid sifaynta, sifaynta dhoobada saliidda, kala saarista wasakhda iwm.

Daawo: shaandhaynta decoction daawada Shiinaha, sifaynta qayb adag, nadiifinta, iyo dawooyinka kale

Elektroonik: Qaabdhismeedka guddiga wareegga, qaybaha elektarooniga ah, aashitada batari, module shucaaca

Daabacaad: sifaynta khad, sifaynta kaarboon, sifaynta, iyo toneryada kale

Qalabka: shaashadda gariirta

Macluumaadka aasaasiga ah

Nooca Tolman: Tolmo Cad iyo Twill Weave

Mesh: 1-635 mesh, Si sax ah

Wire Dia.: 0.022 mm - 3.5 mm, weecasho yar

Ballaca: 190mm, 915mm, 1000mm, 1245mm ilaa 1550mm

Dhererka: 30m, 30.5m ama gooyaa dhererka ugu yaraan 2m

Qaabka daloolka: Square Hole

Walaxda siliga: silig bir ah oo aan lahayn

Mesh Dusha sare: nadiif ah, siman, magnet yar.

Xirmooyinka: Biyo-Cadaynta, Waraaqda Caaga ah, Kas Alwaax ah, Saqafka

Min. Dalabka Tirada: 30 SQM

Faahfaahinta Bixinta: 3-10 maalmood

Tusaale: Lacag Bilaash ah

| Liistada cayiman ee Mesh-xadhkaga birta aan-dhalatada lahayn / marada silig-xidhka leh | |||||

| SHARCIGA CAD IYO TILMAAMAHA | |||||

| Mesh | Dhexroorka siliga | Balaadhka furitaanka | Aagga furitaanka% | ||

| inches | mm | inches | mm | ||

| 1 mesh | 0.135 | 3.5 | 0.865 | 21.97 | 74.8 |

| 2 mesh | 0.12 | 3 | 0.38 | 9.65 | 57.8 |

| 3 mesh | 0.08 | 2 | 0.253 | 6.42 | 57.6 |

| 4 mesh | 0.12 | 3 | 0.13 | 3.3 | 27 |

| 5 mesh | 0.08 | 2 | 0.12 | 3.04 | 36 |

| 6 mesh | 0.063 | 1.6 | 0.104 | 2.64 | 38.9 |

| 8 mesh | 0.063 | 1.6 | 0.062 | 1.57 | 24.6 |

| 10 mesh | 0.047 | 1.2 | 0.053 | 1.34 | 28.1 |

| 12 mesh | 0.041 | 1 | 0.042 | 1.06 | 25.4 |

| 14 mesh | 0.032 | 0.8 | 0.039 | 1.52 | 29.8 |

| 16 mesh | 0.032 | 0.8 | 0.031 | 0.78 | 23.8 |

| 18 mesh | 0.02 | 0.5 | 0.036 | 0.91 | 41.1 |

| 20 mesh | 0.023 | 0.58 | 0.027 | 0.68 | 29.2 |

| 24 mesh | 0.014 | 0.35 | 0.028 | 0.71 | 44.2 |

| 28 mesh | 0.01 | 0.25 | 0.026 | 0.66 | 51.8 |

| 30 mesh | 0.013 | 0.33 | 0.02 | 0.5 | 37.1 |

| 35 mesh | 0.012 | 0.3 | 0.017′ | 0.43 | 33.8 |

| 40 mesh | 0.014 | 0.35 | 0.011 | 0.28 | 19.3 |

| 50 mesh | 0.009 | 0.23 | 0.011 | 0.28 | 30.3 |

| 60 mesh | 0.0075 | 0.19 | 0.009 | 0.22 | 30.5 |

| 70 mesh | 0.0065 | 0.17 | 0.008 | 0.2 | 29.8 |

| 80 mesh | 0.007 | 0.18 | 0.006 | 0.15 | 19.4 |

| 90 mesh | 0.0055 | 0.14 | 0.006 | 0.15 | 25.4 |

| 100 mesh | 0.0045 | 0.11 | 0.006 | 0.15 | 30.3 |

| 120 mesh | 0.004 | 0.1 | 0.0043 | 0.11 | 26.6 |

| 130 mesh | 0.0034 | 0.0086 | 0.0043 | 0.11 | 31.2 |

| 150 mesh | 0.0026 | 0.066 | 0.0041 | 0.1 | 37.4 |

| 165 mesh | 0.0019 | 0.048 | 0.0041 | 0.1 | 44 |

| 180 mesh | 0.0023 | 0.058 | 0.0032 | 0.08 | 33.5 |

| 200 mesh | 0.002 | 0.05 | 0.003 | 0.076 | 36 |

| 220 mesh | 0.0019 | 0.048 | 0.0026 | 0.066 | 33 |

| 230 mesh | 0.0014 | 0.035 | 0.0028 | 0.071 | 46 |

| 250 mesh | 0.0016 | 0.04 | 0.0024 | 0.061 | 36 |

| 270 mesh | 0.0014 | 0.04 | 0.0022 | 0.055 | 38 |

| 300 mesh | 0.0012 | 0.03 | 0.0021 | 0.053 | 40.1 |

| 325 mesh | 0.0014 | 0.04 | 0.0017 | 0.043 | 30 |

| 400 mesh | 0.001 | 0.025 | 0.0015 | 0.038 | 36 |

| 500 mesh | 0.001 | 0.025 | 0.0011 | 0.028 | 25 |

| 635 mesh | 0.0009 | 0.022 | 0.0006 | 0.015 | 14.5 |