mesh silig naxaas cas

Shabakadda siliga naxaasta gaduudan waa walax isku tolan oo leh silig naxaas ah oo nadiif ah (waxyaabaha naxaasta saafiga ah inta badan waa ≥99.95%). Waxay leedahay koronto heer sare ah, conductivity kulaylka, caabbinta daxalka iyo waxqabadka gaashaanka elektromagnetic, waxaana si weyn loogu isticmaalaa qalabka elektiroonigga ah, isgaarsiinta, ciidamada, cilmi baarista sayniska iyo qaybaha kale.

1. Astaamaha alaabta

Walax naxaas ah oo nadiif ah oo sarreeya

Qaybta ugu muhiimsan ee mesh silig naxaas ah waa naxaas (Cu), kaas oo inta badan ka kooban qadar yar oo ah walxo kale (sida aluminium, manganese, iwm.), oo leh nadiif ah in ka badan 99.95%, hubinta xasiloonida walxaha ee meelo kala duwan.

Koronto iyo kuleyl aad u wanaagsan

Copper waxay leedahay koronto iyo kulayl sare waxayna ku habboon tahay codsiyada u baahan korantada wanaagsan, sida isku xirka, dejinta iyo kulaylka qalabka elektaroonigga ah.

Iska caabin daxalka wanaagsan

Copper waxay leedahay iska caabin wanaagsan oo ku saabsan daxalka inta badan deegaanka waxayna ku habboon tahay qurxinta gudaha iyo dibadda, farshaxanimada iyo codsiyada kale.

Aan magnet ahayn

Mesh silig naxaas ah ma aha birlab ah oo ku habboon waqtiyada meesha faragelinta magnetic loo baahan yahay in laga fogaado.

Caag sare

Copper waa sahlan tahay in lagu farsameeyo qaabab kala duwan, kuwaas oo dabooli kara baahiyaha naqshadaha adag waxaana badanaa loo isticmaalaa soo saarista farshaxanimada iyo qurxinta.

2. Habka timaha

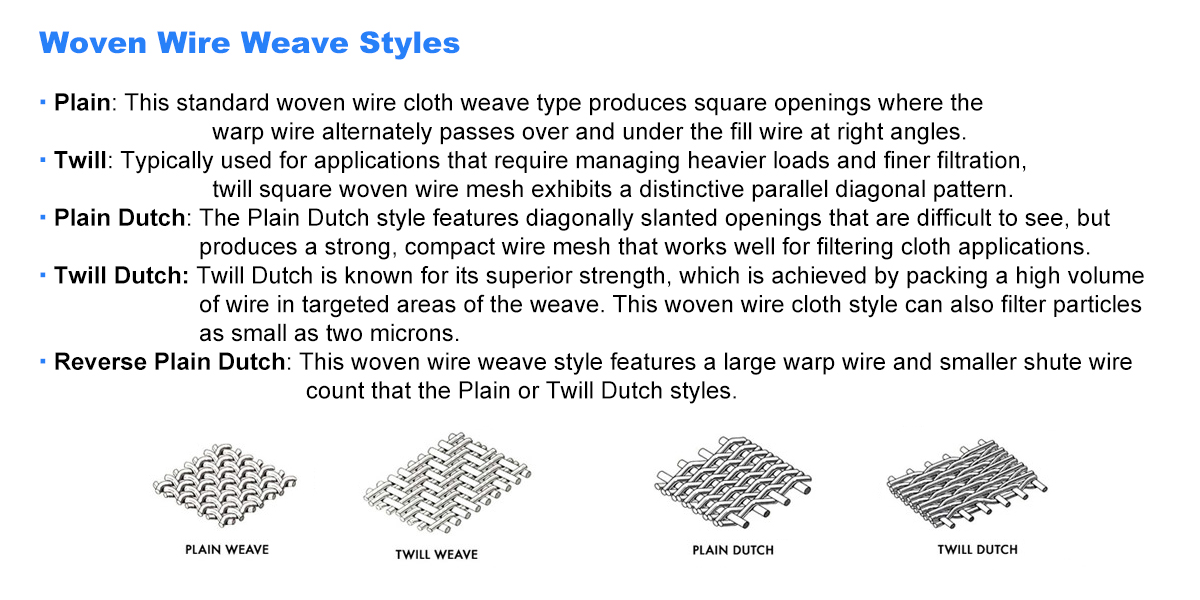

Mesh-ka siliga naxaasta ah waxa lagu toleeyaa hababka soo socda:

Weave cad: Cabbirka mesh wuxuu u dhexeeyaa 2 ilaa 200 meshes, cabirka mesh waa lebis, kaas oo ku habboon sifeynta iyo ilaalinta guud.

Twill weave: Cabbirka mesh-ka ayaa u janjeedha, kaas oo sifeyn kara qaybo yaryar, boodh, iwm., oo ku habboon waqtiyada u baahan sifaynta saxda ah ee saxda ah.

Mesh daloolsan: Daloolka la habeeyey waxaa sameeyay habka shaabadaynta, oo leh daloolin ugu yar oo ah 40 microns, kaas oo inta badan loo isticmaalo kala daadinta kulaylka VC iyo gaashaanka korantada.

Mesh fidsan Rhombus: Kala duwanaanshaha daloolku waa 0.07 mm ilaa 2 mm, kaas oo ku habboon dhisidda gaashaanka iyo gaashaanka hirarka korantada.

3. Tilmaamaha

Dhexroorka xadhigga: 0.03 mm ilaa 3 mm, kaas oo loo habeyn karo iyadoo loo eegayo baahiyaha.

Cabbirka mesh: 1 ilaa 400 meshes, marka uu sareeyo cabbirka mesh-ga, waa uu yaraadaa daloollada

Cabbirka mesh: 0.038 mm ilaa 4 mm, kaas oo buuxiya shuruudaha saxsanaanta shaandhaynta ee kala duwan.

Ballaca: Ballaca caadiga ah waa 1 mitir, ballaca ugu badana wuxuu gaari karaa 1.8 mitir, kaas oo la beddeli karo.

Dhererka: Waxaa laga beddeli karaa 30 mitir ilaa 100 mitir.

Dhumucda: 0.06 mm ilaa 1 mm.

IV. Goobaha codsiga

Qalabka elegtarooniga ah

Waxaa loo isticmaalaa in lagu ilaaliyo faragelinta korantada ee qalabka elektaroonigga ah iyo ka hortagga shucaaca korantada ee saameeya jidhka bini'aadamka iyo qalabka kale. Tusaale ahaan, mesh naxaas ah ayaa inta badan loo isticmaalaa in lagu ilaaliyo shucaaca korantada ee qalabka elektiroonigga ah sida kiisaska kombayutarka, kormeerayaasha, iyo taleefannada gacanta.

Goobta isgaarsiinta

Saldhigyada saldhigga isgaarsiinta, isgaarsiinta dayax-gacmeedka iyo qalabka kale, mesh naxaas ah ayaa loo isticmaali karaa in lagu ilaaliyo faragelinta korantada dibadda iyo hubinta tayada calaamadaha isgaarsiinta.

Goobta militariga

Waxaa loo adeegsadaa gaashaanka elektromagneticiga ah ee qalabka militariga si looga ilaaliyo agabka militariga faragelinta korantada ee cadowga iyo weerarada.

Goobta cilmi-baarista sayniska

Shaybaadhyada, mesh naxaasta waxaa loo isticmaali karaa in lagu ilaaliyo faragelinta korantada ee dibadda oo loo hubiyo saxnaanta natiijooyinka tijaabada.

Qurxinta dhismaha

Maaddaama daahyada gidaarka lagu ilaaliyo, waxay isku daraysaa shaqeynta iyo bilicda waxayna ku habboon tahay qolalka server-ka kombuyuutarka-dhamaadka sare ama xarumaha xogta.

Baaritaanka warshadaha

Waxaa loo isticmaalaa in lagu shaandheeyo alwaaxyada elektarooniga ah iyo kala soocida xalalka isku dhafan, oo leh cabbirro mesh ah oo u dhexeeya 1 mesh ilaa 300 mesh.

Curiyaha kulaylka

200 mesh cad oo mesh ah ayaa loo adeegsaday radiatoorayaasha kiniinka si ay uga caawiyaan qalabka elektiroonigga ah inay kala firdhiyaan kulaylka una wanaajiyaan xasilloonida iyo nolosha adeegga qalabka.

5. Faa'iidooyinka

Nolosha dheer: caabbinta daxalka, iska caabinta heerkulka sare, hoos u dhaca inta jeer ee beddelka, iyo hoos u dhaca kharashka dayactirka.

Saxnaanta sare: Shabagga daloolku waxa uu gaadhi karaa cabbirka daloolka heerka-yar si uu u daboolo baahiyaha sifaynta saxda ah.

Habaynta: Dhexroorka siliga, lambarka mesh, cabbirka iyo qaabka ayaa loo habeyn karaa iyadoo loo eegayo baahida macaamiisha.

Ilaalinta deegaanka: Maaddada naxaasta ah dib ayaa loo warshadayn karaa waxayna buuxinaysaa shuruudaha horumar waara.

| Mesh | Wire Dia (inji) | Silig Dia (mm) | Furitaanka (inji) |

| 2 | 0.063 | 1.6 | 0.437 |

| 2 | 0.08 | 2.03 | 0.42 |

| 4 | 0.047 | 1.19 | 0.203 |

| 6 | 0.035 | 0.89 | 0.131 |

| 8 | 0.028 | 0.71 | 0.097 |

| 10 | 0.025 | 0.64 | 0.075 |

| 12 | 0.023 | 0.584 | 0.06 |

| 14 | 0.02 | 0.508 | 0.051 |

| 16 | 0.018 | 0.457 | 0.0445 |

| 18 | 0.017 | 0.432 | 0.0386 |

| 20 | 0.016 | 0.406 | 0.034 |

| 24 | 0.014 | 0.356 | 0.0277 |

| 30 | 0.013 | 0.33 | 0.0203 |

| 40 | 0.01 | 0.254 | 0.015 |

| 50 | 0.009 | 0.229 | 0.011 |

| 60 | 0.0075 | 0.191 | 0.0092 |

| 80 | 0.0055 | 0.14 | 0.007 |

| 100 | 0.0045 | 0.114 | 0.0055 |

| 120 | 0.0036 | 0.091 | 0.0047 |

| 140 | 0.0027 | 0.068 | 0.0044 |

| 150 | 0.0024 | 0.061 | 0.0042 |

| 160 | 0.0024 | 0.061 | 0.0038 |

| 180 | 0.0023 | 0.058 | 0.0032 |

| 200 | 0.0021 | 0.053 | 0.0029 |

| 250 | 0.0019 | 0.04 | 0.0026 |

| 325 | 0.0014 | 0.035 | 0.0016 |