titanium anode

Titanium anode (inozivikanwawo setitanium-based metal oxide coated anode, DSA, Dimensionally Stable Anode) ndeyepamusoro-inoita electrode zvinhu zvinoshandiswa zvakanyanya mumunda we electrochemistry. Iyo ine yakanakisa corrosion kuramba, yakakwira catalytic chiitiko uye hupenyu hurefu.

1. Hunhu hunokosha hwetitanium anode

- Dimensional kugadzikana: Iyo electrode spacing inoramba isina kuchinjika panguva ye electrolysis process, kuve nechokwadi yakagadzikana sero voltage.

- Strong corrosion resistance: Inokodzera asidhi yakasimba, alkali yakasimba uye Cl⁻-ine midhiya, ine corrosion resistance inodarika iyo yegraphite nelead anode.

- Yakaderera inoshanda voltage: Yakaderera overpotential yeokisijeni / chlorine shanduko, kuchengetedza 10% -20% simba.

- Hupenyu hurefu: Muindasitiri yechlor-alkali, nguva yehupenyu inogona kusvika makore matanhatu, nepo iyo yegraphite anode inongova 8 mwedzi.

- Yakakwira yazvino density: Inotsigira 17A/dm² (graphite anode ingori 8A/dm²), inovandudza kugadzirwa kwakanaka.

2. Nzvimbo huru dzekushandisa

(1) Chlor-alkali indasitiri

- Electrolysis yebrine kugadzira chlorine uye caustic soda, titanium anode inogona kuderedza sero voltage uye kunatsiridza chlorine kuchena.

- Tsiva graphite anode kudzivirira kusvibiswa kwe electrolyte.

(2) Kugadziriswa kwemvura yakasviba

- Electrocatalytic oxidation: Degrade organic matter mukudhinda nekudhaya, mishonga, uye coking tsvina yemvura, ine COD yekubvisa mwero unosvika 90%.

-Sodium hypochlorite jenareta: Electrolyze brine kugadzira mushonga wekuuraya utachiona, unoshandiswa kuchenesa tsvina yechipatara uye yekushambira mvura yemvura.

-Radioactive tsvina yemvura kurapwa: Electrolytic kudzoreredza kweradioactive simbi senge uranium uye plutonium.

(3) Electroplating industry

-Inoshandiswa nickel plating, chromium plating, goridhe plating, nezvimwe kuvandudza kufananidzwa kweiyo plating layer uye kuderedza kusvibiswa kwemhinduro.

- Iko kushanduka kweokisijeni overpotential ndeye 0.5V yakaderera pane iyo inode inode, iyo inochengetedza simba zvakanyanya.

(4) Electrolytic metallurgy

- Bvisa simbi semhangura, zinc, uye nickel, tsiva inode inode, uye dzivirira kusvibiswa kwecathode.

-Inokodzera yakakwira yazvino density (senge 8000A/m²) uye nhete inter-electrode spacing (5mm) mamiriro.

(5) Simba idzva uye kugadzirwa kwehydrogen

-Kugadzirwa kweHydrogen ne electrolysis yemvura: Deredza kushanduka kweokisijeni kudarika uye kunatsiridza kushanda nesimba.

- Solid-state bhatiri: inoshandiswa kugadzira titanium-based plate kugadzira.

(6) Zvimwe zvikumbiro

- Kudzivirirwa kweCathodic: anti-corrosion yezvivakwa zvesimbi zvemugungwa, ine hupenyu hwebasa hweanopfuura makore gumi.

- Electrochemical synthesis: senge kugadzirira kwemakemikari emakemikari uye epakati pemishonga.

3. Coating process uye kusarudzwa

- Common coatings:

- Ruthenium (RuO₂): inokodzera chlor-alkali indasitiri, inopesana neCl⁻ corrosion.

- Iridium (IrO₂): yakasimba acid inopikisa, yakakodzera kurapwa kwemvura.

- Platinum coating: inoshandiswa kune yakakwira-kuchena titanium electrolysis, inopesana nekupisa kwakanyanya (600 ℃).

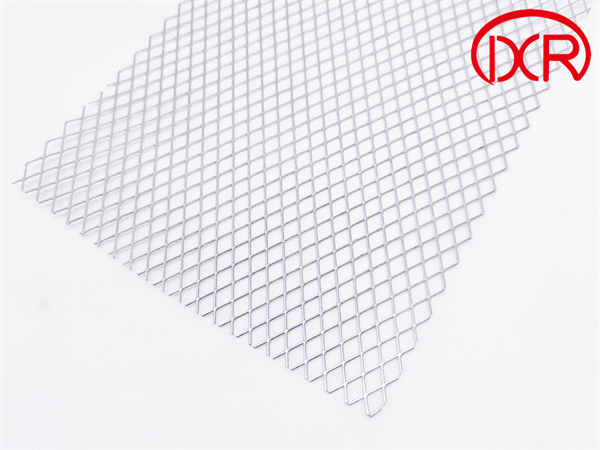

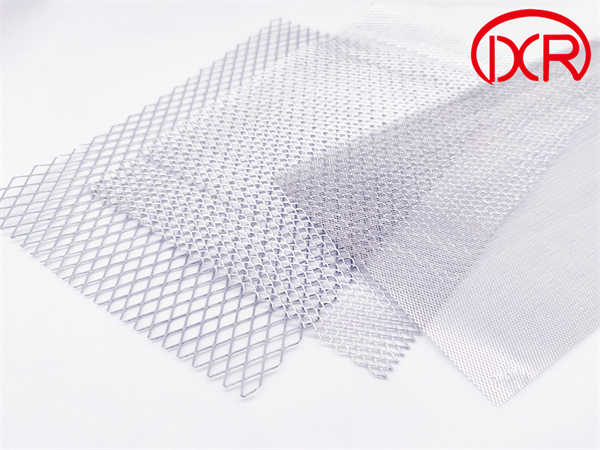

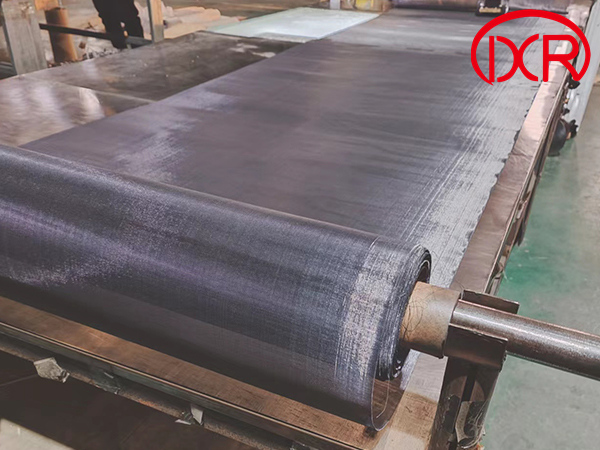

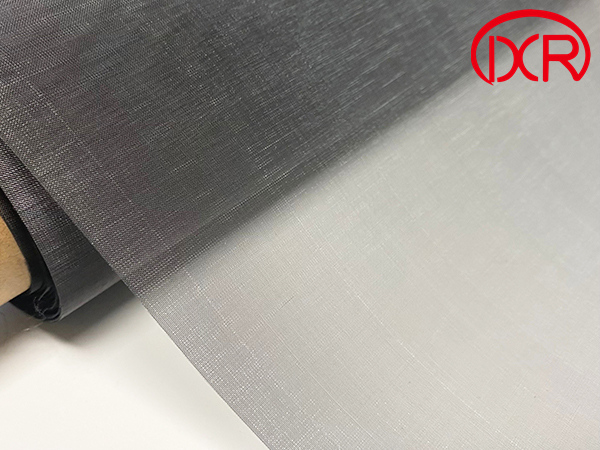

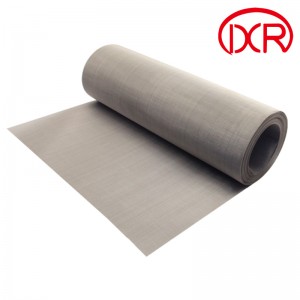

- Chimiro fomu: ndiro, chubhu, mesh, waya, nezvimwewo, inogona kugadzirwa zvinoenderana nezvinodiwa.

4. Kuchengetedza uye kuwedzera kwehupenyu

-Kugara kuchenesa: sukurudza nemvura yakasvibiswa mushure mekuvhara kuti udzivise kuiswa kwechiyero.

- Dzivisa kukuvadzwa kwemuchina: kukuvadzwa kweplatinamu kunokonzeresa kukurumidza kuora kwetitanium substrate.

- Electrolytic activation: dzosera kurapwa kwazvino maawa ega ega 3000 kuti ubvise iyo passivation layer.

5. Mafambiro ebudiriro yeramangwana

- Composite coatings: zvakadai seplatinum-iridium gradient coatings, zvichiwedzera kuderedza kushanduka kweokisijeni overpotential (rabhoritari yasvika 1.25V).

-Kutarisa kwakangwara: ma sensors akasanganiswa anotarisisa kurasikirwa kwekuputira munguva chaiyo.

- Kudzivirirwa kwezvakatipoteredza uye mashandisirwo emagetsi matsva: senge akasimba-state mabhatiri uye inoshanda hydrogen kugadzirwa.