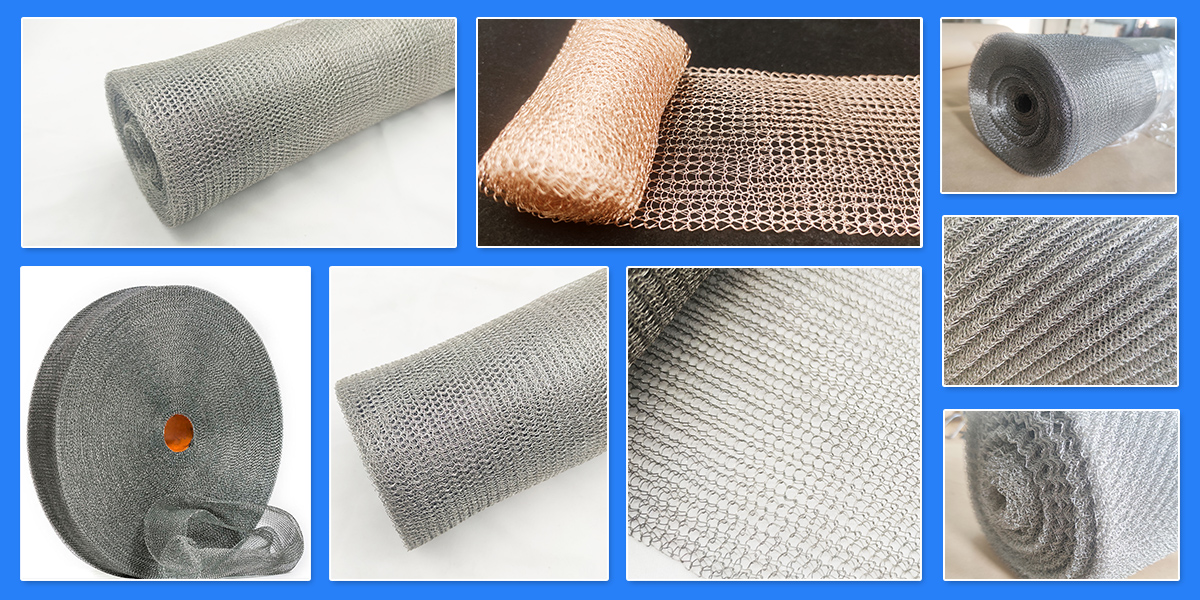

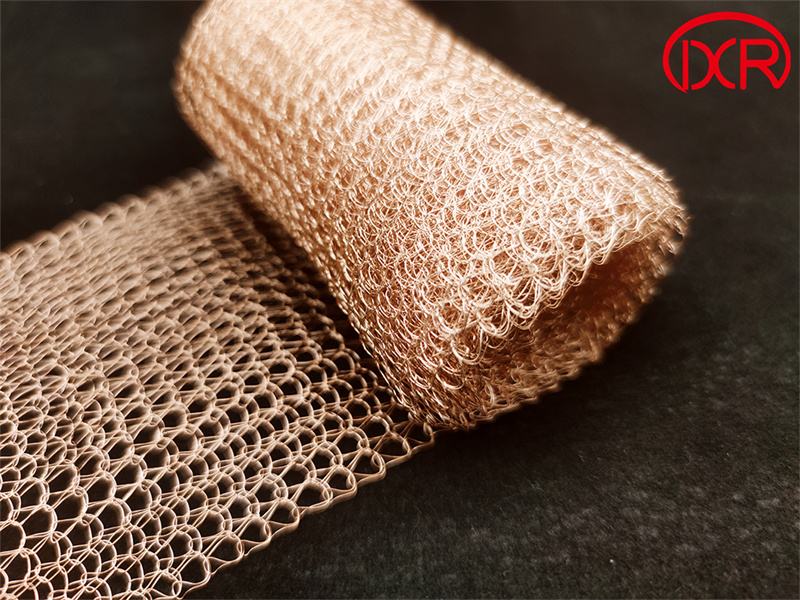

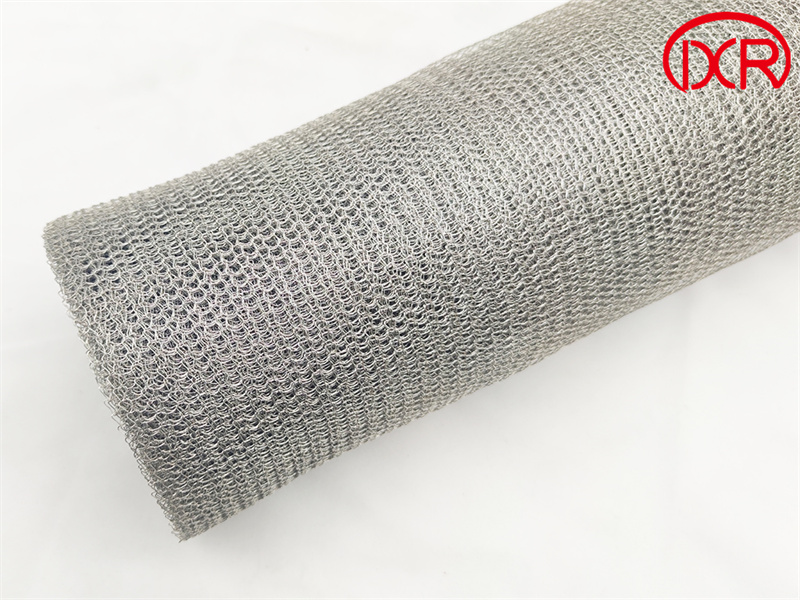

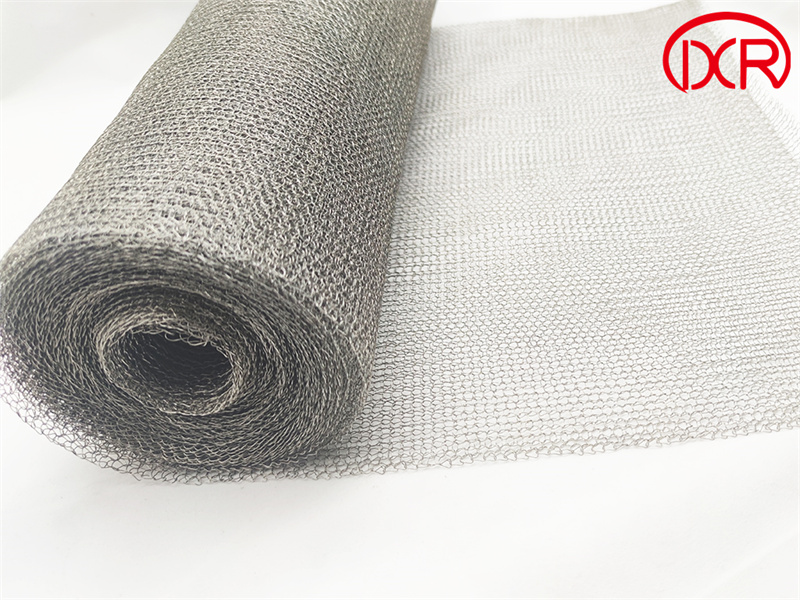

mhangura yakarukwa waya mesh

Mhangurayakarukwa waya meshinoshandiswa zvakanyanya mundima yeindasitiri nekuda kweiyo yakanakisa corrosion resistance, thermal conductivity uye plasticity.

1. Mhangura yakarukwa waya mesh kupatsanurwa uye demisting

Wire mesh demister: inoshandiswa kupatsanura madonhwe emvura (fog) mugasi mushongwe (senge distillation shongwe, absorption shongwe, evaporators), nekurongeka kwesefa kwe3 ~ 5μm uye kushanda zvakanaka kwe98% ~ 99.8%.

Mamiriro ekushandisa:

Petroleum refining (senge catalytic cracking units, natural gas desulfurization towers).

Kugadzirwa kwemakemikari (kucheneswa kwemagasi ane acid akadai sasulfuric acid, hydrochloric acid, acetic acid).

Indasitiri yemishonga (solvent recovery, tsvina gasi kurapwa).

2. Environmental protection engineering

Desulfurization uye demisting: bvisa madonhwe anotakurwa neSO₂gasi mune flue gasi desulfurization (FGD) masisitimu.

Kugadziriswa kwemvura yakasviba: inoshandiswa sekuzadza mumatangi eaeration kuwedzera kushanda kweokisijeni.

3. Mechanical uye indasitiri yemotokari

Mhepo compressor/firiji system: sefa mafuta-mvura musanganiswa mumhepo yakamanikidzwa.

Kuderedza ruzha uye kubatwa nekutya: senge porous inzwi-inotora zvinhu, deredza ruzha rwemidziyo.

4. Electronics uye minda yezvokurapa

Electromagnetic shielding: kushandisa conductivity yemhangura ye electromagnetic interference (EMI) kuchengetedza kweiyo chaiyo zviridzwa.

Yepamusoro-chaiyo kusefa: senge yekurapa mhepo yekuchenesa midziyo, yekupedzisira-yakachena gasi kusefa muindasitiri yesemiconductor.

5. Zvimwe zvinoshandiswa zvakakosha

Yakakwira tembiricha nharaunda: mhangura inoshingirira kune yakakwira tembiricha (inonyungudika 1083℃), yakakodzera kuvira kwemhepo inopisa uye boiler inopedza gasi kurapwa.

Midziyo yemurabhoritari: yakagadziridzwa madiki-masefa anoshandiswa kuMhangura yakarukwa waya mesh kusangana mumakemikari reactor.