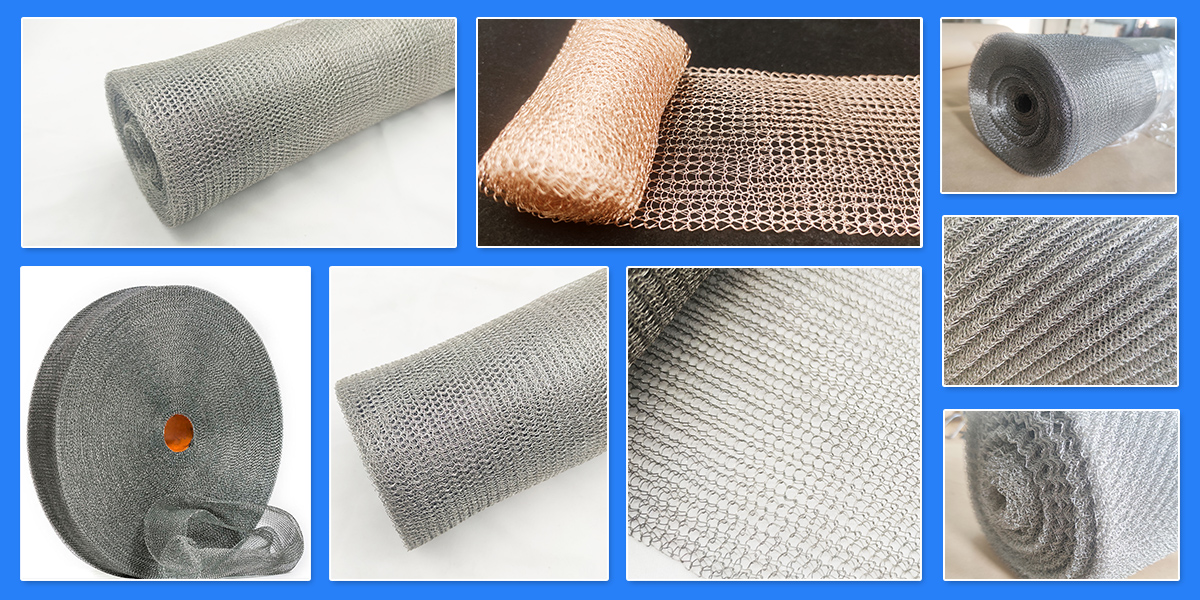

mkuwa woluka waya mauna

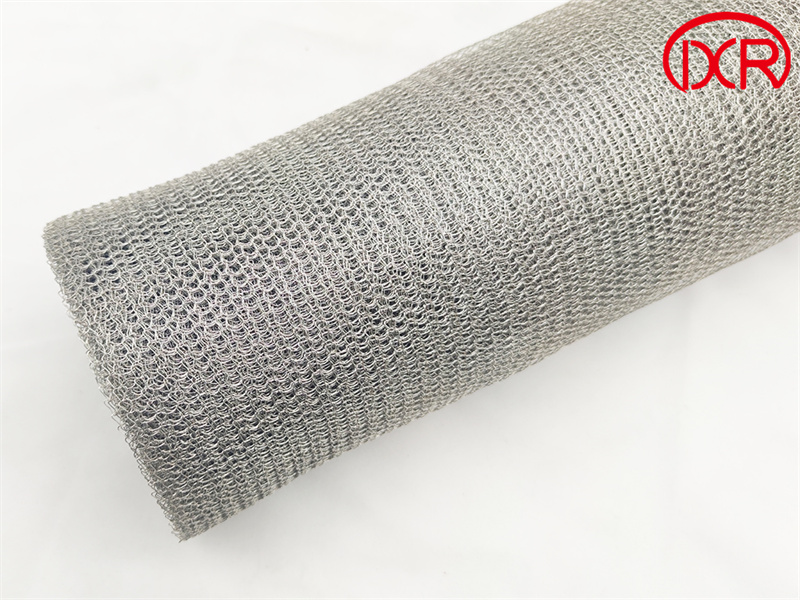

Mkuwaoluka waya maunaamagwiritsidwa ntchito kwambiri m'mafakitale chifukwa cha kukana kwambiri kwa dzimbiri, matenthedwe matenthedwe ndi mapulasitiki.

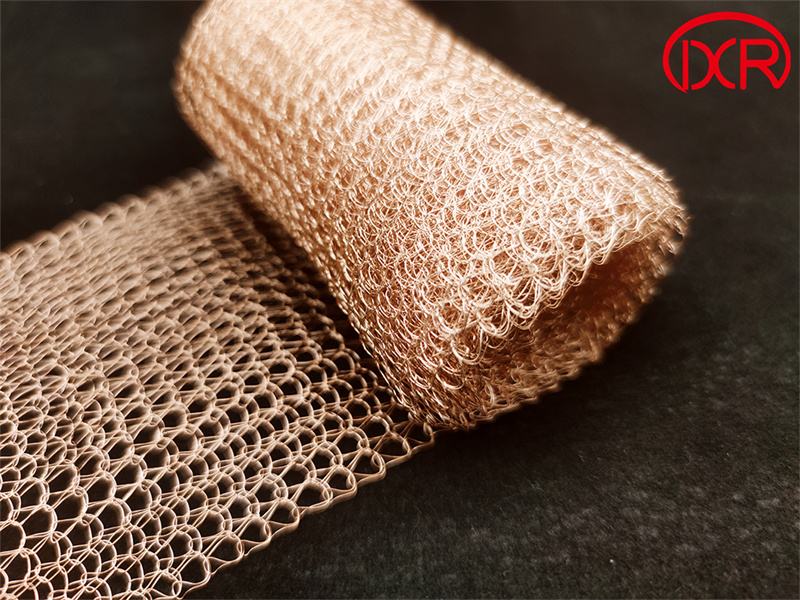

1. Copper knitted waya mauna kulekana ndi demisting

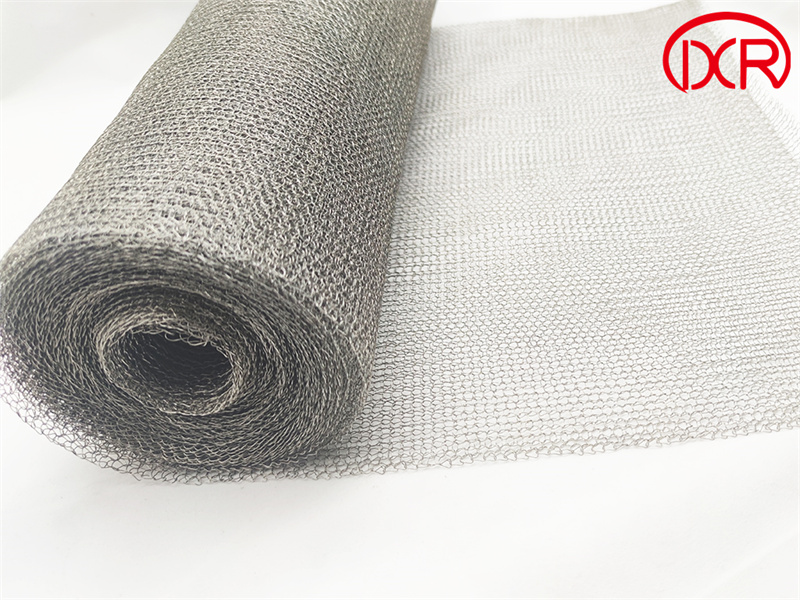

Wire mesh demister: amagwiritsidwa ntchito kulekanitsa madontho amadzimadzi (chifunga) mu gasi munsanja (monga distillation tower, mayamwidwe nsanja, evaporators), ndi kusefera kolondola kwa 3 ~ 5μm ndi mphamvu ya 98% ~ 99.8%.

Zochitika zantchito:

Kuyenga mafuta (monga mayunitsi ong'ambika, nsanja za gasi desulfurization).

Kupanga mankhwala (kuyeretsa mpweya wa acidic monga sulfuric acid, hydrochloric acid, acetic acid).

Makampani opanga mankhwala (kubwezeretsa zosungunulira, chithandizo cha gasi wa zinyalala).

2. Umisiri woteteza chilengedwe

Desulfurization ndi demisting: chotsani madontho otengedwa ndi SO₂gas mu flue gas desulfurization (FGD) machitidwe.

Kuchiza kwamadzi otayira: kumagwiritsidwa ntchito ngati zodzaza m'matanki aeration kuti muwonjezere kuyendetsa bwino kwa mpweya.

3. Makampani opanga makina ndi magalimoto

Air kompresa/firiji dongosolo: fyuluta mafuta osakaniza madzi mu mpweya woponderezedwa.

Kuchepetsa phokoso ndi mayamwidwe owopsa: monga porous-absorbsorption, kuchepetsa phokoso la zida.

4. Zamagetsi ndi zamankhwala

Electromagnetic shielding: kugwiritsa ntchito ma conductivity a mkuwa pachitetezo cha electromagnetic interference (EMI) pazida zolondola.

Kusefedwa kolondola kwambiri: monga zida zoyeretsera mpweya wamankhwala, kusefera kwa gasi kopitilira muyeso mumakampani a semiconductor.

5. Ntchito zina zapadera

Malo otentha kwambiri: mkuwa umalimbana ndi kutentha kwambiri (malo osungunuka 1083℃), oyenera ng'anjo za mpweya wotentha ndi chithandizo cha gasi wa boiler.

Zipangizo za labotale: Zosefera zazing'ono zosinthidwa makonda zimagwiritsidwa ntchito polumikizana ndi Copper yoluka waya muzitsulo zamagetsi.