titanium anode

Titanium anode (nke a makwaara dị ka anode oxide nke dabeere na titanium, DSA, Dimensionally Stable Anode) bụ ihe elektrọd na-arụ ọrụ nke ọma n'ọtụtụ ebe n'ọhịa nke electrochemistry. Ọ nwere ezigbo nguzogide corrosion, ọrụ catalytic dị elu na ogologo ndụ.

1. Isi njirimara nke titanium anode

- Nkwụsi ike akụkụ: oghere electrode na-agbanwe agbanwe n'oge usoro electrolysis, na-eme ka voltaji cell kwụsiri ike.

- Nguzogide corrosion siri ike: Kwesịrị ekwesị maka acid siri ike, alkali siri ike na mgbasa ozi Cl⁻ nwere, yana nguzogide corrosion karịrị nke graphite na lead anodes.

- Voltaji na-arụ ọrụ dị ala: ike dị ala maka evolushọn oxygen / chlorine, na-echekwa ike 10% -20%.

- Ogologo ndụ: Na ụlọ ọrụ chlor-alkali, ogologo ndụ nwere ike iru afọ 6, ebe nke graphite anode bụ naanị ọnwa 8.

- Njupụta dị elu ugbu a: Na-akwado 17A / dm² (graphite anode bụ naanị 8A / dm²), na-eme ka nrụpụta nrụpụta dị mma.

2. Mpaghara ngwa ngwa

(1) Chlor-alkali ụlọ ọrụ

- Electrolysis nke brine iji mepụta chlorine na caustic soda, titanium anode nwere ike ibelata voltaji cell ma melite ịdị ọcha chlorine.

- Dochie anode graphite iji zere mmetọ electrolyte.

(2) Ọgwụgwọ mmiri mkpofu

- Electrocatalytic oxidation: Mebie ihe organic na ibipụta na ịcha akwa, ọgwụ, na coking mmiri mkpofu, yana ọnụego mwepụ COD ruru 90%.

- Sodium hypochlorite generator: Electrolyze brine iji mepụta ọgwụ na-efe efe, nke a na-eji maka nsị ụlọ ọgwụ na ọgwụgwọ mmiri ọdọ mmiri.

- Ngwọta mmiri mkpofu redioaktivu: mgbake electrolytic nke ọla redioaktivu dị ka uranium na plutonium.

(3) Ụlọ ọrụ eletrik

- A na-eji nickel plating, chromium plating, gold plating, etc. iji melite uniformity nke plating oyi akwa na ibelata plating ngwọta mmetọ.

- Oxygen evolushọn overpotential bụ 0.5V ala karịa nke lead anode, nke na-azọpụta ike nke ukwuu.

(4) Electrolytic metallurgy

- Wepụ ọla dị ka ọla kọpa, zinc na nickel, dochie anode ndu, ma zere mmetọ cathode.

- Kwesịrị ekwesị maka njupụta dị ugbu a dị elu (dị ka 8000A/m²) yana ọnọdụ oghere inter-electrode dị warara (5mm).

(5) Ike ọhụrụ na mmepụta hydrogen

- Mmepụta hydrogen site na electrolysis nke mmiri: Belata mgbanwe ikuku oxygen karịrị ike ma melite arụmọrụ ike.

- Batrị steeti siri ike: ejiri maka nrụpụta efere dabere na titanium.

(6) Ngwa ndị ọzọ

- Nchedo Cathodic: mgbochi corrosion nke ihe owuwu igwe mmiri, yana ndụ ọrụ karịa afọ 10.

- Ngwakọta electrochemical: dị ka nkwadebe nke organic ogige na ọgwụ intermediates.

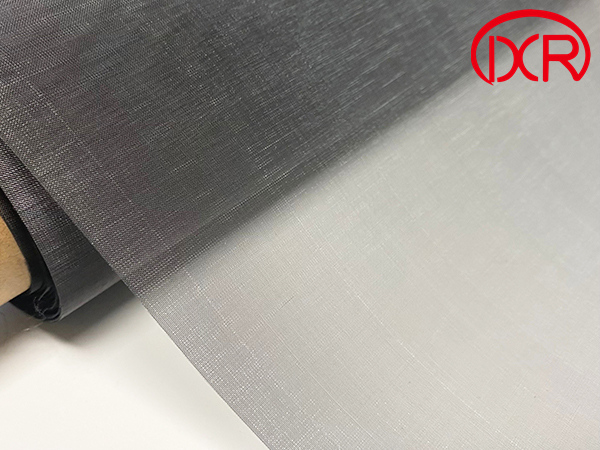

3. Usoro mkpuchi na nhọrọ

- Mkpuchi a na-ahụkarị:

- Ruthenium (RuO₂): dabara maka ụlọ ọrụ chlor-alkali, na-eguzogide ọgwụ Cl⁻ corrosion.

- Iridium (IrO₂): nguzogide acid siri ike, adabara maka ọgwụgwọ mmiri mkpofu.

- Platinum mkpuchi: eji maka elu-ọcha titanium electrolysis, eguzogide elu okpomọkụ (600 ℃).

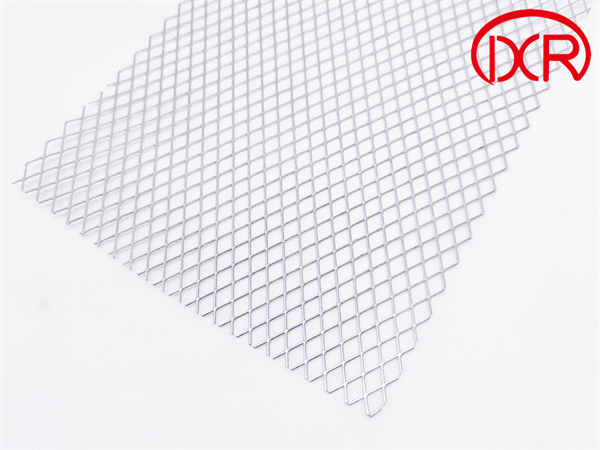

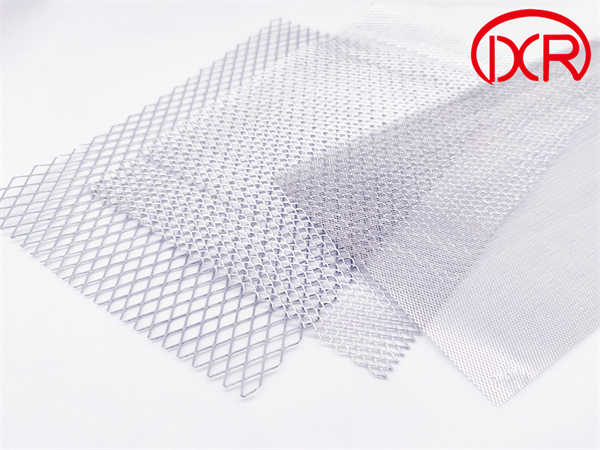

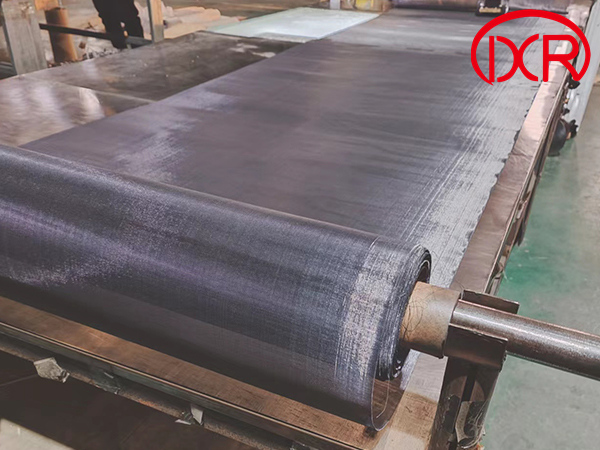

- Ụdị nhazi: efere, tube, ntupu, waya, wdg, nwere ike ịhazi dịka mkpa dị.

4. Nlekọta na ndọtị ndụ

- Nhicha mgbe niile: jiri mmiri deionized sachaa mgbe emechiri ya ka ịzenarị nkwụnye ego.

- Zere mmebi nke igwe: mmebi nke oyi akwa platinum ga-eme ka corrosion ngwa ngwa nke mkpụrụ titanium.

- Mgbalite ọkụ eletrik: tụgharịa ọgwụgwọ ugbu a kwa awa 3000 iji wepụ oyi akwa passivation.

5. Ọdịnihu mmepe ọnọdụ

- Ihe mkpuchi mejupụtara: dị ka platinum-iridium gradient mkpuchi, na-ebelata mgbanwe ikuku oxygen karịrị ike (ụlọ nyocha eruola 1.25V).

- Nleba anya nke ọgụgụ isi: ihe mmetụta agbakwunyere na-enyocha ọnwụ mkpuchi ozugbo.

- Nchedo gburugburu ebe obibi na ngwa ike ọhụrụ: dịka batrị siri ike na mmepụta hydrogen nke ọma.