Piv nrog rau 60-mesh lim, 80-mesh lim yog finer. Tus naj npawb mesh feem ntau qhia txog cov naj npawb ntawm qhov ib nti hauv ntiaj teb, thiab qee qhov yuav siv qhov loj ntawm txhua qhov mesh. Rau lub lim, tus xov tooj mesh yog tus naj npawb ntawm qhov ntawm qhov screen ib square inch. Tus naj npawb mesh Qhov siab dua tus naj npawb mesh, qhov ntau mesh qhov, thiab qhov kev lim dej zoo dua; qhov qis mesh tus naj npawb, qhov tsawg mesh qhov, thiab cov coarser cov lim.

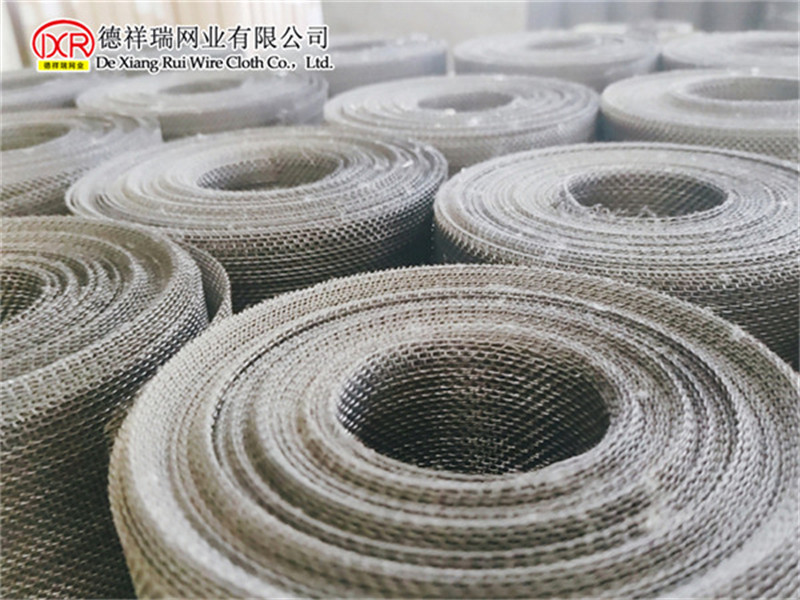

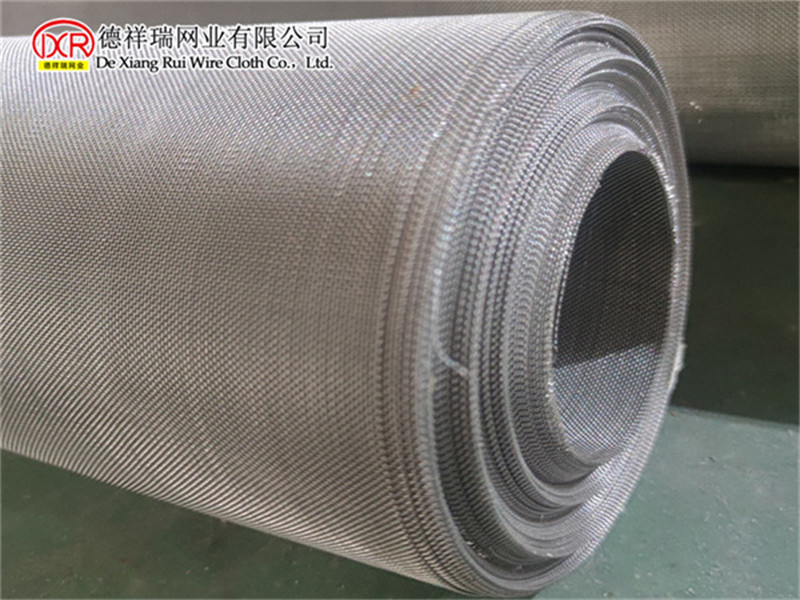

Lim mesh, hu ua lim mesh, yog ua los ntawm cov hlau mesh ntawm txawv meshes. Nws feem ntau muab faib ua hlau lim mesh thiab textile fiber lim mesh. Nws txoj haujlwm yog lim cov khoom molten ntws thiab ua kom cov khoom ntws tsis kam, yog li ua tiav pom. Nws tuaj yeem tshem tawm txhua yam impurities thiab txhim kho cov nyhuv ntawm kev sib xyaw lossis plasticizing. Cov lim dej muaj cov khoom xws li kub tsis kam, acid tsis kam, alkali tsis kam, thiab hnav tsis kam. Nws yog tsuas yog siv nyob rau hauv roj av, tshuaj lom neeg kev lag luam, machinery manufacturing thiab lwm yam lag luam.

Post lub sij hawm: Mar-27-2024