anode titanium

ʻO Titanium anode (ʻike pū ʻia ʻo ka anode metala oxide coated titanium, DSA, Dimensionally Stable Anode) he mea electrode hana kiʻekiʻe i hoʻohana nui ʻia ma ke kahua o ka electrochemistry. Loaʻa iā ia ke kūpaʻa corrosion maikaʻi, ka hana catalytic kiʻekiʻe a me ke ola lōʻihi.

1. Nā hiʻohiʻona kumu o ka anode titanium

- Paʻa paʻa ʻana: ʻAʻole i hoʻololi ʻia ka spacing electrode i ka wā o ke kaʻina electrolysis, e hōʻoia ana i ka volta cell stable.

- Ke kū'ē i ka corrosion ikaika: He kūpono no ka waika ikaika, alkali ikaika a me Cl⁻-containing media, me ka pale ʻana i ka corrosion ma mua o ko ka graphite a me nā anodes alakaʻi.

- Ka uila hana haʻahaʻa: Haʻahaʻa overpotential no ka oxygen / chlorine evolution, e mālama ana i ka ikehu 10% -20%.

- Ke ola lōʻihi: Ma ka ʻoihana chlor-alkali, hiki ke ola i 6 mau makahiki, ʻoiai ʻo ka graphite anode he 8 mahina wale nō.

- Kiʻekiʻe kiʻekiʻe o kēia manawa: Kākoʻo iā 17A/dm² (graphite anode he 8A/dm² wale nō), e hoʻomaikaʻi ana i ka hana hana.

2. Nā wahi noi nui

(1) ʻOihana Chlor-alkali

- Electrolysis o ka brine e hana i ka chlorine a me ka soda caustic, hiki i ka titanium anode ke hōʻemi i ka uila kelepona a hoʻomaikaʻi i ka maʻemaʻe chlorine.

- Hoʻololi i ka anode graphite e pale aku i ka hoʻohaumia electrolyte.

(2) Hoʻomaʻemaʻe wai ʻino

- Electrocatalytic oxidation: E hoʻohaʻahaʻa i ka mea olaola i ka paʻi ʻana a me ka hoʻoluʻu ʻana, ka lāʻau lapaʻau, a me ka wai ʻawaʻawa coking, me ka helu hoʻohemo COD a hiki i 90%.

- ʻO ka sodium hypochlorite generator: Electrolyze brine e hoʻohua i ka disinfectant, hoʻohana ʻia no ka hoʻomaʻemaʻe o ka haukapila a me ka mālama wai ʻauʻau.

- Hoʻomaʻamaʻa i ka wai ʻino radioactive: Hoʻihoʻi electrolytic o nā metala radioactive e like me ka uranium a me ka plutonium.

(3) ʻOihana Electroplating

- Hoʻohana ʻia no ka nickel plating, chromium plating, gula plating, etc.

- ʻO ka oxygen evolution overpotential he 0.5V haʻahaʻa ma mua o ka anode alakaʻi, kahi e mālama nui ai i ka ikehu.

(4) ʻO ka metallurgy electrolytic

- Wehe i nā metala e like me ke keleawe, ka zinc, a me ka nickel, e hoʻololi i ka anode alakaʻi, a pale aku i ka hoʻohaumia cathode.

- He kūpono no nā kūlana kiʻekiʻe o kēia manawa (e like me 8000A/m²) a me nā kūlana inter-electrode spacing (5mm).

(5) Ka ikehu hou a me ka hana hydrogen

- Hana ʻia ka hydrogen e ka electrolysis o ka wai: E hōʻemi i ka hoʻonui ʻana o ka oxygen i ka overpotential a hoʻomaikaʻi i ka pono o ka ikehu.

- ʻO ka pākaukau paʻa paʻa: hoʻohana ʻia no ka hana ʻana i ka pā paʻa titanium.

(6) Nā noi ʻē aʻe

- Palekana Cathodic: anti-corrosion o nā hale kila moana, me ke ola lawelawe ʻoi aku ma mua o 10 mau makahiki.

- Electrochemical synthesis: e like me ka hoʻomākaukau ʻana i nā mea hoʻohui organik a me nā mea waena lāʻau.

3. Kaʻina hana uhi a me ke koho

- Nā uhi maʻamau:

- Ruthenium (RuO₂): kūpono no ka ʻoihana chlor-alkali, kū i ka Cl⁻ corrosion.

- Iridium (IrO₂): ke kūpale ikaika i ka waika, kūpono no ka mālama ʻana i ka wai ʻino.

- Platinum coating: hoʻohana ʻia no ka electrolysis titanium maʻemaʻe kiʻekiʻe, kū i ka wela kiʻekiʻe (600 ℃).

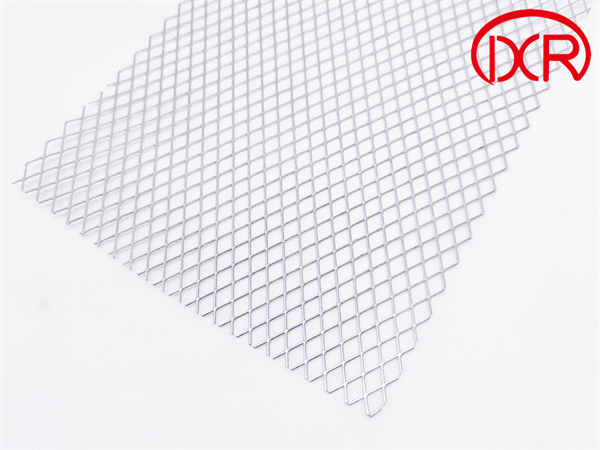

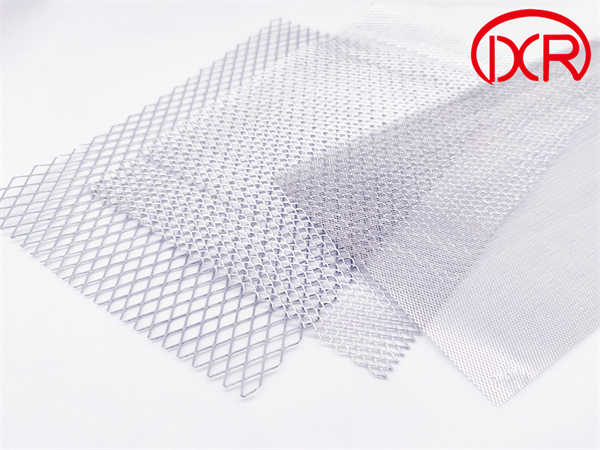

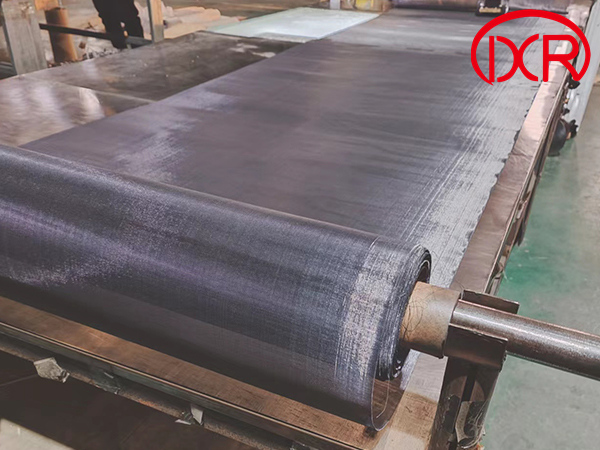

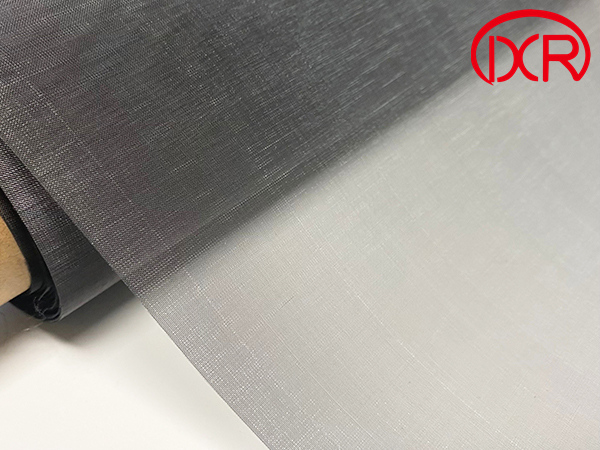

- Ke ʻano hoʻolālā: pā, tube, mesh, wire, etc., hiki ke hoʻopili ʻia e like me nā pono.

4. Ka mālama a me ka hoʻonui ola

- Hoʻomaʻemaʻe maʻamau: holoi me ka wai deionized ma hope o ka pani ʻana e pale i ka waiho ʻana o ka unahi.

- Hōʻalo i ka pōʻino mechanical: ʻo ka pōʻino i ka papa platinum e hoʻopōʻino wikiwiki i ka substrate titanium.

- Hoʻoulu Electrolytic: hoʻohuli i ka mālama ʻana i kēia manawa i kēlā me kēia 3000 hola e wehe i ka papa passivation.

5. Nā ʻano hoʻomohala e hiki mai ana

- Nā mea hoʻopili hoʻohui: e like me ka platinum-iridium gradient coatings, e hōʻemi hou ana i ka nui o ka hoʻonui ʻana o ka oxygen (ua hiki ke keʻena hana i ka 1.25V).

- Ka nānā ʻana naʻauao: nānā nā mea ʻike hoʻohui i ka nalowale o ka uhi i ka manawa maoli.

- Ka mālama ʻana i ke kaiapuni a me nā noi ikehu hou: e like me nā ʻōhua paʻa a me ka hana hydrogen kūpono.